PAM polymer preparation unit Description

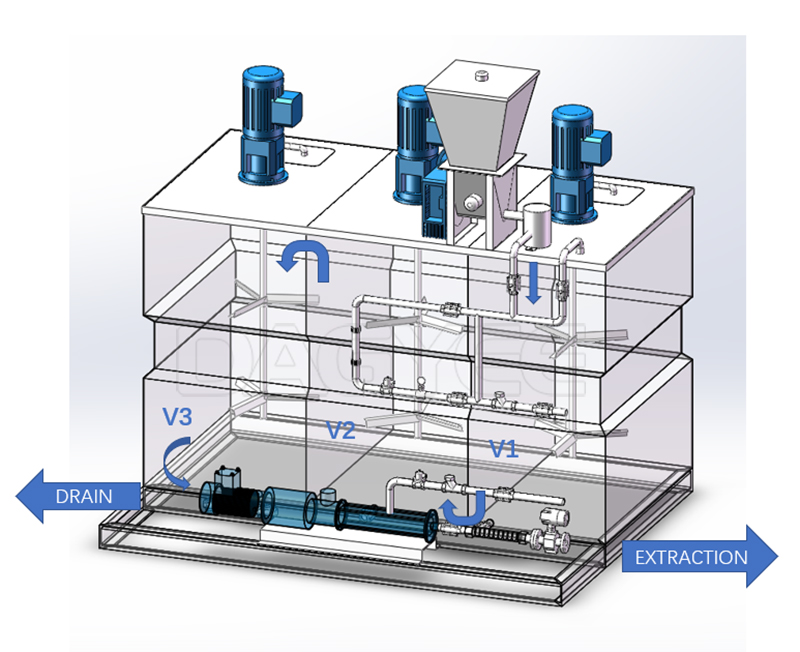

Polymer preparation units are automated systems for the preparation of liquid or powdered polymers, designed for the fully automated dosing of polymer solutions.

The Polymer Dosing System can be used to batch flocculation aids for the preparation of ready-to-use polymer solutions. The design is optimized to ensure that the polymer maturation process is completed with minimal footprint.

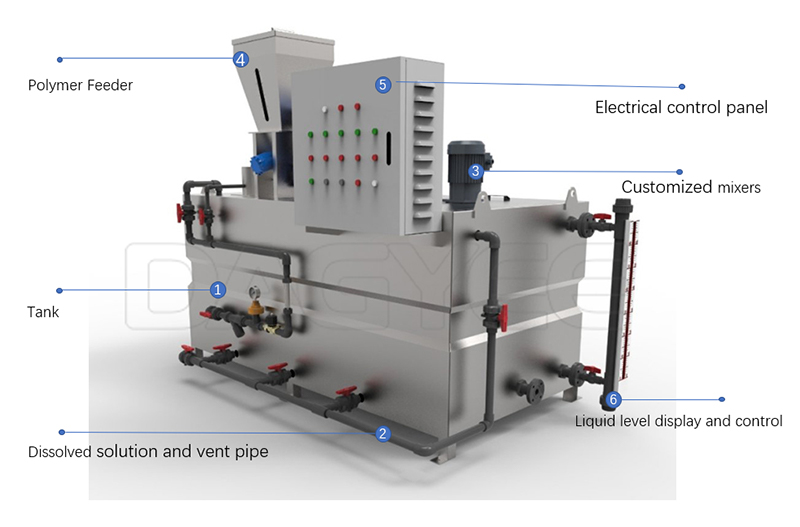

Polymer dosing device

Polymer dosing device is composed of hopper, push screw, electric heater and etc. The effective volume of the hopper can meet the dosage for a long time which is equipped with sight glasses for observing material level monitored by the dry powder level meter. The push screw driven by the high-precision reducer can satisfy the dosage. The electric heater can be installed in the discharge pipe of push screw, and it can prevent the powder from caking.

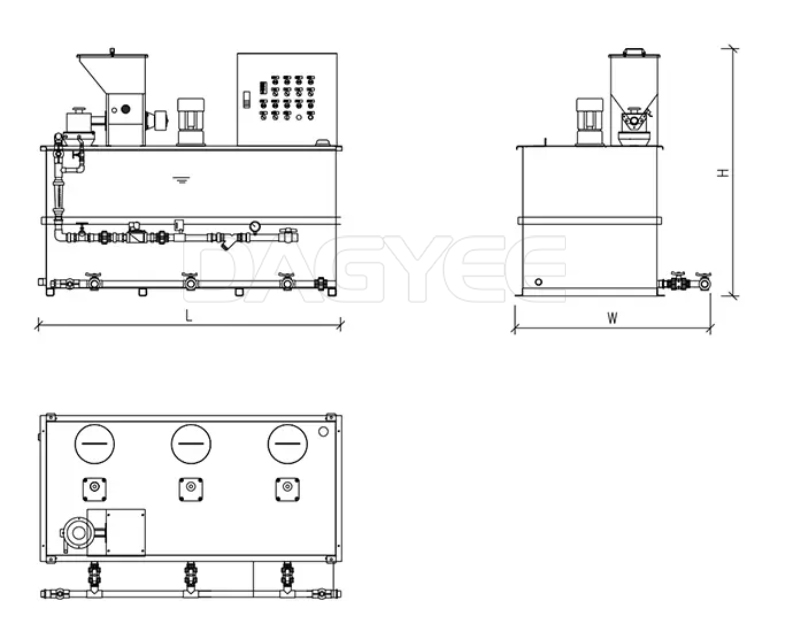

Polymer dissolving device

Polymer dissolving device is composed of pre-soaking device, tank, and 3 sets of mixers. The pre-soaking device is to infiltrate and mix the polymer powder in advance. The 3 tanks are precast mixing tank, homogeneous slaking tank and solution storage tank, in which there is a mixer correspond to guarantee the homogeneity.

Water supply device

Water supply device is composed of pipeline, manual ball valve, filter, pressure gauge, solenoid valve, stop valve, and the rotor flow meter, etc.

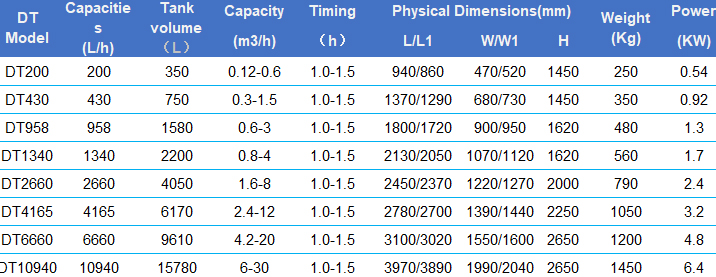

PAM Polymer Preparation Unit Model

PAM Polymer Preparation Advantage

PAM Polymer Preparation Application

The use of polymers or floculants considerably improves the separation process between the solid/liquid phases for applications in:

These flocculants, in powder and emulsion form, are very high molecular weight polymers. To ensure efficiency of the separation process, the preparation of the dilute polymer solution (2 to 5 g/l) is critical. The POLYPACK® unit employs rigourous technical standards and features which ensure optimum and consistent flocculant preparation.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China