Static Screen Wastewater Description

When wastewater flows into a treatment plant, a static screen sits in front of the remaining wastewater equipment. Wastewater enters the system, passing through a stationary static screen first to remove as many solids as possible.

Think of it like a mesh screen that keeps bugs from entering your window at home. In this case, it’s a durable screen that catches particles like plastics, feminine products, foods that weren’t digested, hardened particles of grease, and paper products.

Items that get captured are composted or removed and taken to a landfill. Many plants compost them over time, and that compost can be used in forests. This makes it easier for the next stages of wastewater treatment, such as grit removal.

In addition to a municipal wastewater treatment system, static screens benefit businesses that are under orders to pre-treat industrial wastewater or who want to do their part. It includes companies like chemical processing plants, paper mills, breweries, food processing plants, and plastic and metal processing plants. If you have a stormwater system, they are fantastic for removing plastics, trash, and fallen sticks and branches after a storm.

Static Screen Wastewater Works

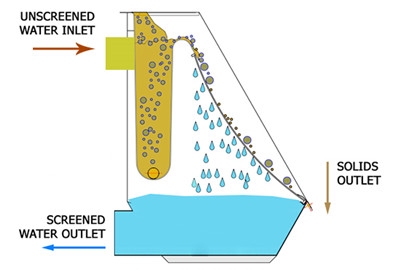

During dry weather conditions the flow to the treatment works will pass underneath the screens in the dry weather flow channel.

In a storm event the inflow rate to the chamber will exceed the outflow rate causing water levels to rise within the chamber and spill through the screens.

The Hydro-Static® Screen is mounted over the dry weather flow channel so that the flow passes up and through the screen during a storm event. Solids and floatables are trapped below the screen and returned to the sanitary continuation flow. Screened effluent is discharged to a receiving waterway.

An emergency overflow weir is incorporated into the screen should the peak design flow be exceeded.

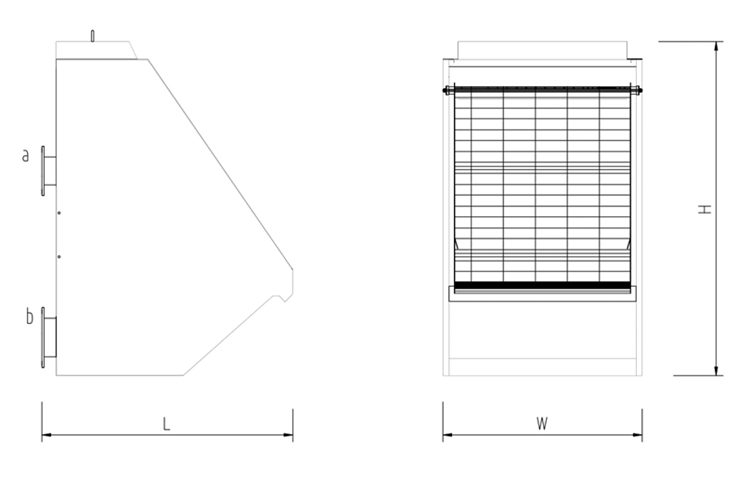

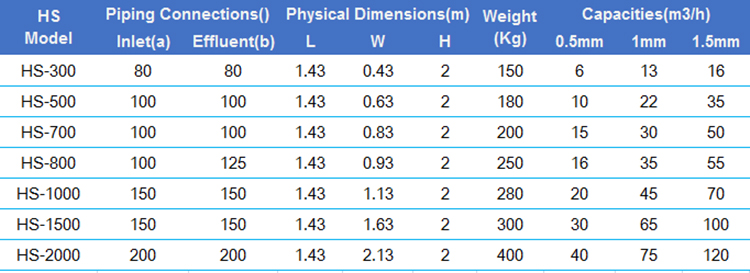

Static Screen Wastewater Model

Static Screen Wastewater Feature

Static Screen Wastewater Application

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China