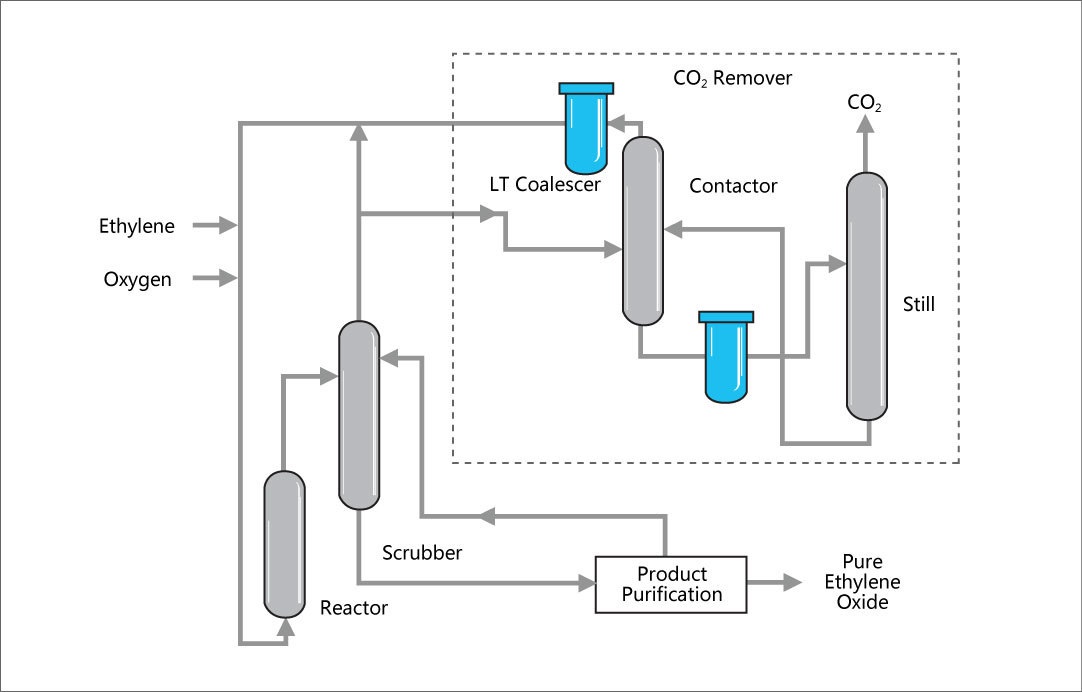

Ethylene Oxide Production Process

Ethylene Glycol

Due to the high precision requirements of the slicing and fiber industries, fine filtration of raw materials is essential.

Ethylene Oxide

Can serve as a deicing agent

Circulating water filtration

Process Overview

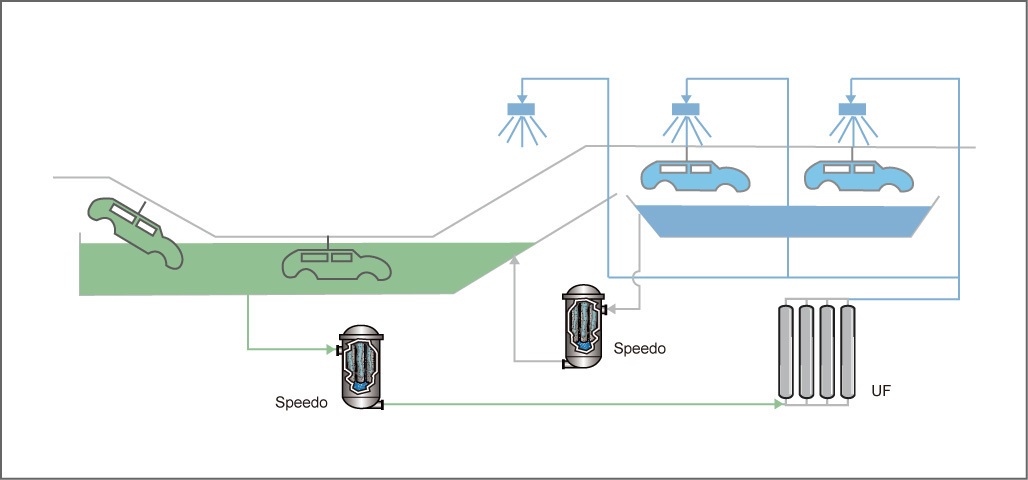

Water washing primarily removes residual degreasers, phosphating agents, and contaminants from workpiece surfaces. This step can be performed via spray or immersion methods. The counter-current washing process employs a single immersion wash as a supplement to the initial spray wash, with a secondary immersion wash supplementing the second spray wash. Washing solution is filtered and reused; bag filters are recommended.

Problem Description

Automotive finishing plants' spray booths are major water consumers, with pre-treatment wastewater accounting for over 80% of total booth drainage. Consequently, effective filtration to meet recycling standards is critical for reducing pure water usage and wastewater discharge, thereby achieving energy conservation and consumption reduction.

Product Advantages

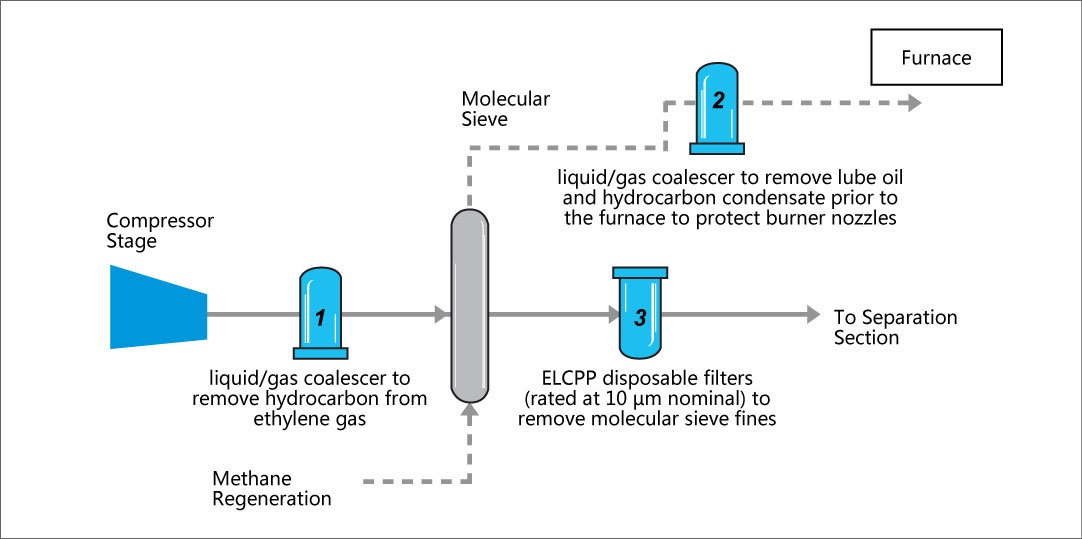

Ethylene Compressor & Compressor Protection

Ethylene Compressor and Molecular Sieve System

Despite the use of demisters, the molecular sieve beds in ethylene production have a service life of less than three years. After compression, hydrocarbons in the ethylene concentrate into fine mist, which is difficult for demisters to separate. This fine mist, along with compressor lubricating oil, degrades the performance and lifespan of the molecular sieves.

The lifespan of molecular sieve resin depends on the number of regeneration cycles. During each cycle, elevated temperatures and reduced pressure cause hydrocarbons to evaporate from the sieves, simultaneously inducing molecular sieve cracking. The resulting wear from fissures necessitates costly replacement of the sieve material.

Install a gas-liquid coalescer downstream of the demister in ethylene production to remove aerosols containing hydrocarbons as small as 1µm and aqueous aerosols.

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China