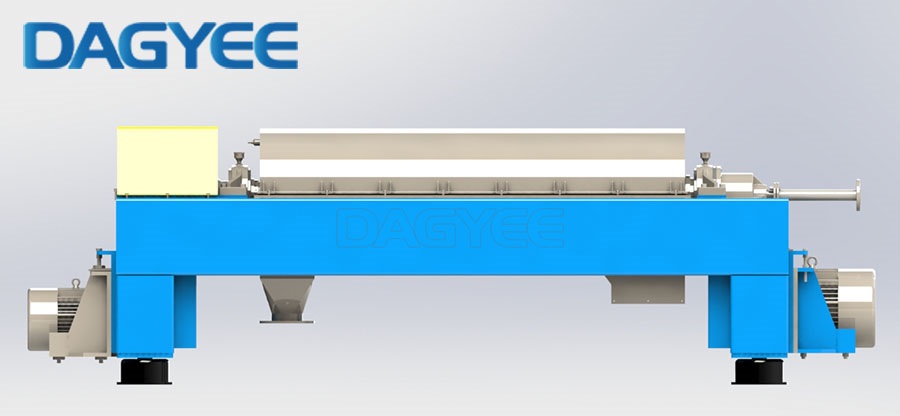

Decanter centrifuge descriptions

When solid/liquid mixtures with a high portion of solids need to be separated, decanter centrifuges are the solution of choice. In contrast to chamber filter presses, these solid shell scroll centrifuges or decanters operate continuously. High centrifugal forces separate the finely distributed solid particles from the suspension.

The modular design of our decanters makes them useful in a wide variety of industries throughout the world – from Australia to Zambia. The centrifuges are adapted optimally to the specific application. Applications range from sludge dewatering to classification or wet classification to the sorting of solids.

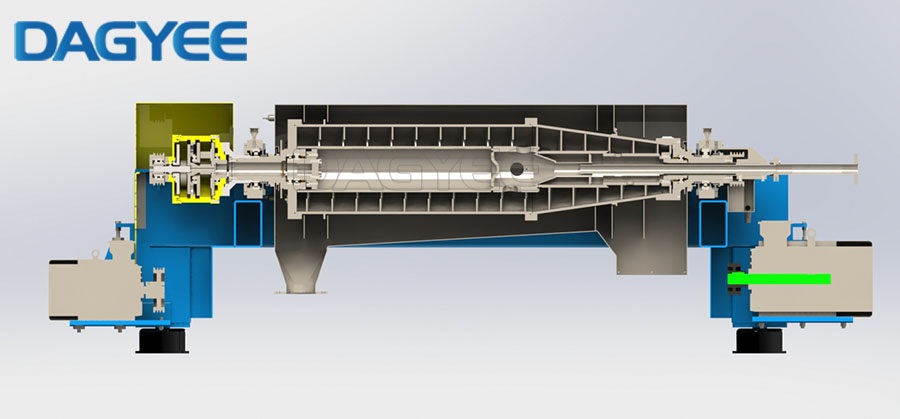

How does a decanter centrifuge work?

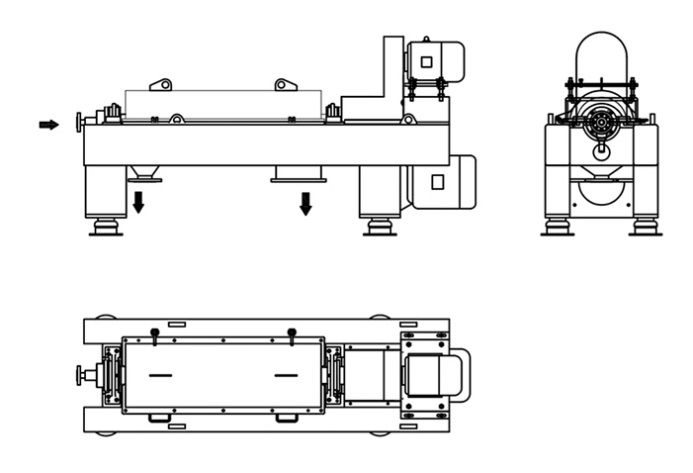

1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

3: The bowl rotates at high speeds to induce centrifugal forces.

4: High speed rotation separates the solid material from the liquid in a matter of seconds.

5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries.

Decanter centrifuge advanced operation capabilities

Clarification

Clarification removes suspended solids from a liquid of lower density across a particle size range from 1 to 10,000 microns. By increasing centrifugal force, even submicron particles can be separated, making this process ideal for high-purity applications in chemicals, mining, and waste management.

Classifying

Through controlled reduction of residence time, the decanter achieves sharp separation cuts for particle-size classification down to the submicron range. This capability is essential for processes requiring precise particle distribution and custom engineering solutions.

Liquid/liquid separation

The efficiently separates immiscible liquid phases of different densities, with or without solids present. This is critical for oil recovery and industrial wastewater treatment, where mechanical dewatering and centrifugal separation reduce reprocessing and disposal costs.

Thickening

Fine solids separated from the liquid can be thickened in a hindered settling mode, utilizing the cylindrical section of the bowl for maximum compression. This improves solids handling and reduces downstream load, contributing to operational efficiency.

Compression and dewatering

Compactive dewatering combines drainage and compression to achieve a higher degree of dryness, even with compressible solids. The degree of dewatering depends on solids characteristics, machine settings, and required dryness levels. Optimized conveyor and cone geometry, along with differential speed control, ensure stable discharge of pasty or shear-sensitive solids—key for waste management and cost reduction.

Counter-current washing

Integrated washing systems allow efficient, cost-effective removal of contaminants by separate discharge of wash liquor over multiple sections. This reduces chemical and water consumption, aligning with sustainability and process optimization goals.

Mixing and re-suspension

Special discharge geometries enable solids to be mixed with liquid directly at the outlet, eliminating the need for additional mixing vessels. This feature simplifies plant design and enhances operational efficiency.

Automation and innovation

Control systems for smart operation

Control systems stabilize separation quality, automate setpoints, and provide diagnostics that support predictive service strategies. As the “brain” behind the process, strengthens industrial automation and helps maintain equipment reliability through better visibility, alarms, and optimization tools.

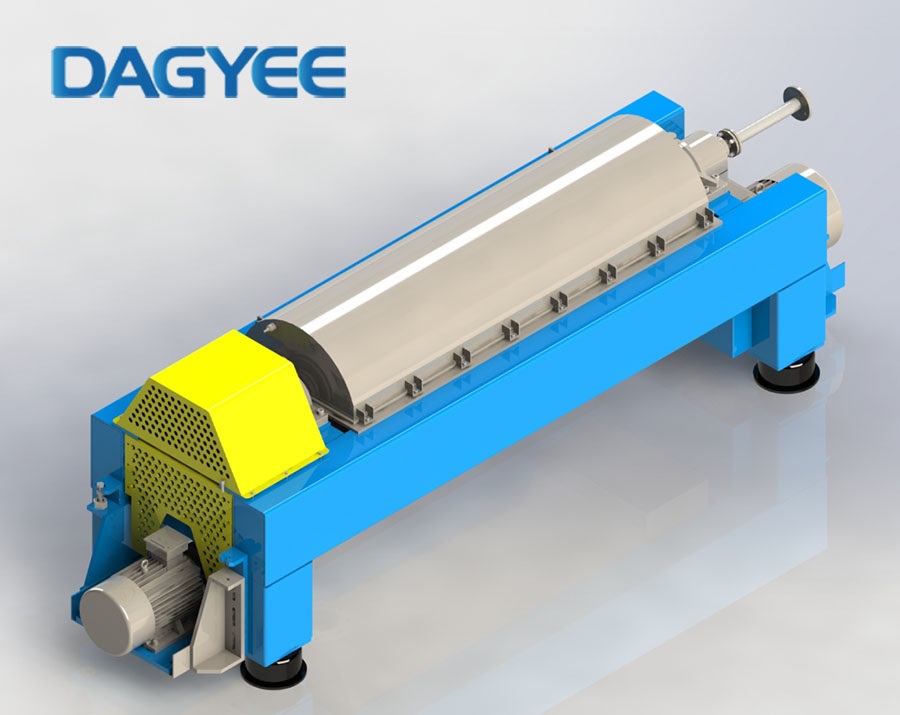

Engineered for tough conditions

A broad choice of materials of construction, wear protection, and sealing options extends service life in abrasive or corrosive duties. Features like CIP, optimized bearings and seals, and gas-tight/pressurized casings are designed to lower maintenance effort while keeping performance high.

Options that boost performance

Depending on application, It can be equipped with energy-recovery weir plates, specialized feed systems to reduce particle breakage, and multiple drive/gearbox configurations—each selected to match duty conditions and performance targets.

Decanter centrifuge specifications

| Model |

Drum diameter mm |

Length mm |

Maximum speed rpm |

Highest separation factor g |

Mixture capacity m³/h |

|---|---|---|---|---|---|

| LW250-900 | 250 | 900 | 5000 | 3500 | 0.5-3 |

| LW350-1500 | 350 | 1500 | 3800 | 2850 | 1-5 |

| LW400-1200 | 400 | 1200 | 3400 | 2581 | 1-8 |

| LW400-1600 | 400 | 1600 | 3400 | 2581 | 2-10 |

| LW400-1800 | 400 | 1800 | 3400 | 2581 | 2-12 |

| LW450-1800 | 450 | 1800 | 3200 | 2572 | 5-20 |

| LW450-2000 | 450 | 2000 | 3200 | 2572 | 5-25 |

| LW530-2280 | 530 | 2280 | 2800 | 2350 | 10-50 |

| LW600-2400 | 600 | 2400 | 2600 | 2265 | 15-65 |

| LW650-2600 | 650 | 2600 | 2400 | 2100 | 20-80 |

| LW720-2500 | 720 | 2500 | 2200 | 1950 | 25-90 |

| LW800-2560 | 800 | 2560 | 2000 | 1800 | 30-100 |

| LW800-3200 | 800 | 3200 | 2000 | 1800 | 30-110 |

| LW900-3200 | 800 | 3200 | 1800 | 1650 | 30-150 |

Why choose the DAGYEE decanter centrifuge?/Decanter centrifuge advantages

1. Fully automated operation, meaning less operator intervention required

2. Lower volume cake, reducing storage area/transport requirements

3. Enclosed operation for cleaner/ less housekeeping

4. Less sensitivity to changing feed characteristics, meaning less adjustment

5. Longer maintenance intervals (belt filters can require frequent replacement)

6. No requirement for continuous wash water, so less water is required

7. Simple, heavy-duty construction

Decanter centrifuge key features

Decanter centrifuge applications

1. Industrial and municipal wastewater treatment

2. Oil & gas drilling mud/fluid control

3. Washing, separation and dewatering of starch

4. Mycelium and zymotic fluid separation for antibiotic

5. Dewatering of soybean and wheat protein

6. Dewatering of fish power and fish meat

7. Dewatering of vinasse

8. Clarification and extraction of fruit juice

9. Separation and purification for animal and vegetable oil

10. Production and purification of olive oil, palm oil, avocado oil

11. Separation and purification for coal tar

12. Grading of kaolin and graphite

13. Grading and dewatering of dyestuff and pigment

14. Froth flotation for cleaned coal and dewatering of coal mud

15. Grading and dewatering of minerals

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China