Externally rotary fed drum screen description

The Externally Fed Rotary Drum Screen is a reliable self-cleaning wedge wire screen for industrial wastewater operations.

This screening technology performs particularly well in wastewater with high oil or grease loadings as well as scum applications that can blind other types of screens.

It is used for fine screening primary sewage influent at the headworks as well as screening of clarifier scum.

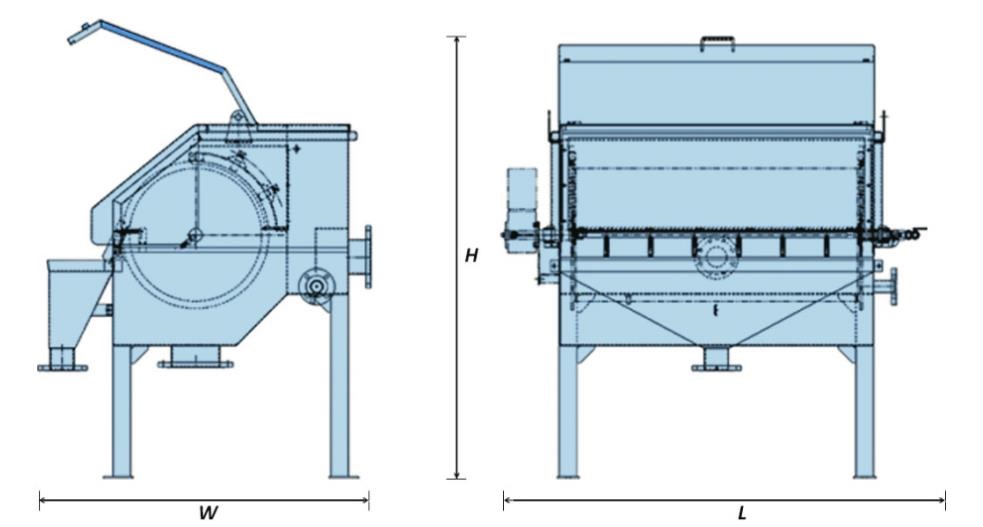

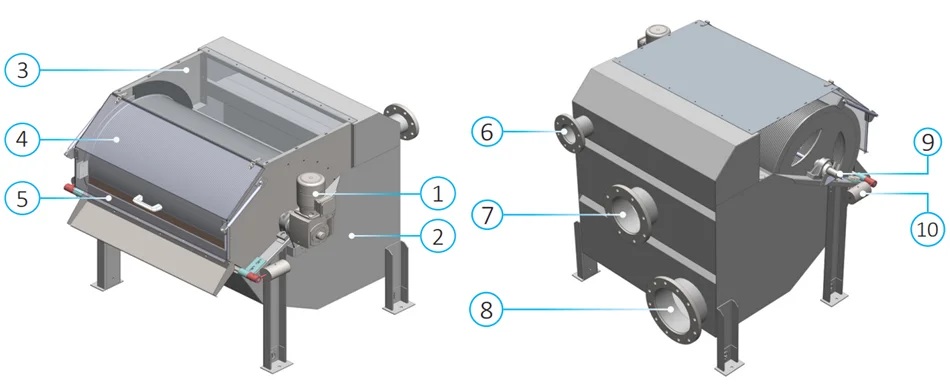

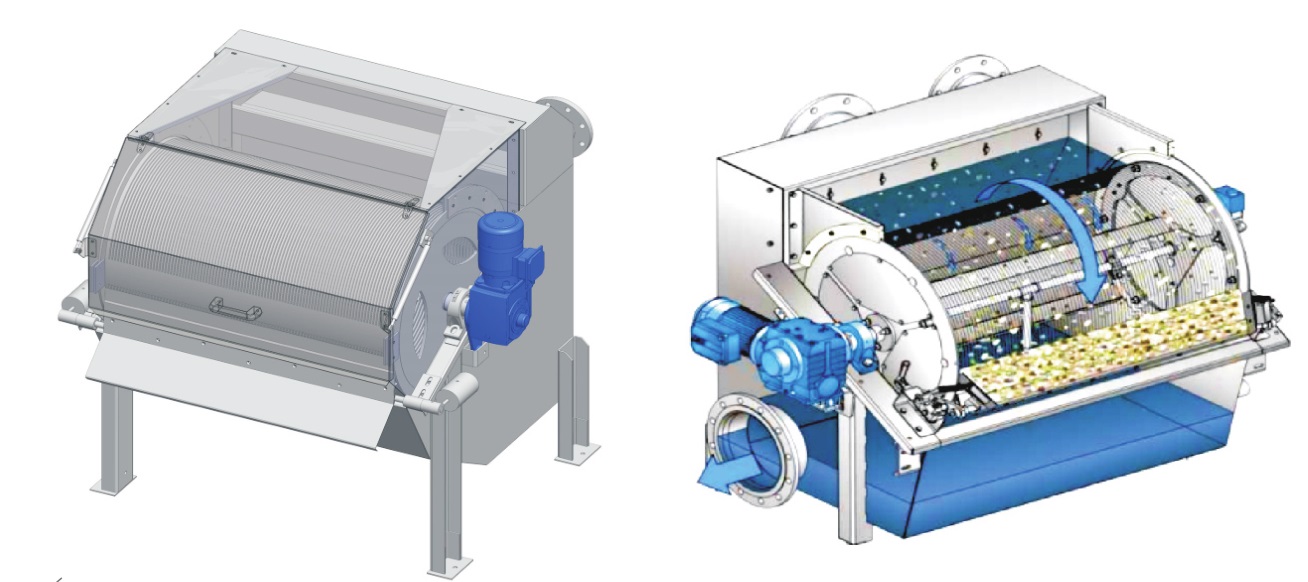

The Externally Fed Rotary Drum Screen is constructed of slotted stainless wedge wire formed into a cylindrical drum that rotates on two pillow block bearings.

The screen typically has openings ranging from 0.100 to 0.010 inches and features 100% overflow protection from blinding for flows up to 5.0 mgd.

Externally rotary fed drum screen function

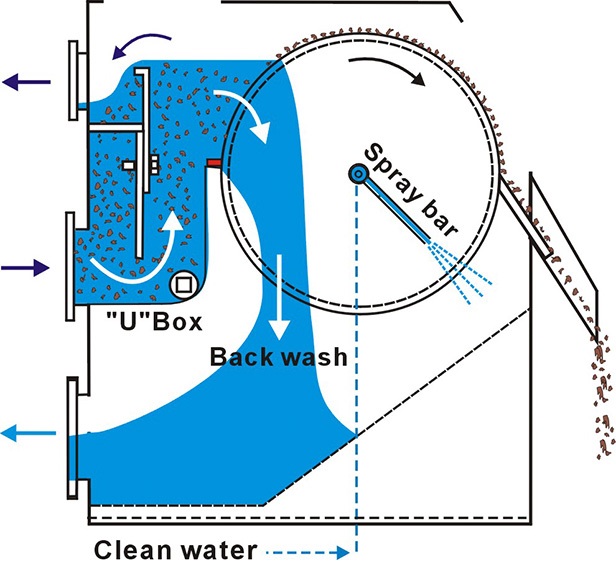

Raw influent enters a headbox which distributes the flow evenly across the full length of the rear, upper external surface of the rotating drum screen.

As water passes through the screen, solids are retained on the outside of the screen drum and are carried by rotation to the front of the screen where they are removed by a fixed doctor blade.

The screened water cascades down the inside of the drum and falls through the bottom, where it creates a vigorous backwash action.

This action, combined with the use of internal water sprays, self-cleans the drum on every revolution.

Screened solids can then be discharged into a dumpster, press or conveyor.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. 100% overflow protection for designed flow up to 5.0 mgd.

2. More material recovery for re-use.

3. Customized to fit into existing infrastructure.

Externally rotary fed drum screen feature

1. All 304 stainless steel construction.

2. Headbox with overflow protection.

3. Solid unitary frame.

4. Wedge wire drum.

5. Doctor blade assembly with Monel blade.

6. Internal spray bar.

Externally rotary fed drum screen application

Typical applications: separation of various solids and sludges from municipal and industrial wastewater, food processes, pulp and paper production and rendering processes;

removal of extruded pellets from cooling baths; and separation of debris from any variety of plant and equipment-cleaning processes.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China