Static Mixers

Choose from our selection of static mixers, including PVC inline pipe mixers, stainless steel inline pipe mixers, and more.

Static Mixer Function

DAGYEE Static mixers are devices used in various industries to blend different components within a fluid stream. In addition, they come in different types such as helical, blade, and non-fouling mixers. Also, Helical static mixers utilize twisted elements to promote mixing. Also, blade mixers have stationary blades that help in blending, and non-fouling mixers are designed to resist clogging or accumulation during operation.

On the other hand, tank mixers are used for mixing substances within tanks or containers. In addition, they can be top-mounted, providing efficient mixing from above. Also, portable mixers offer flexibility and can be moved between different tanks. Additionally, side-entry mixers are convenient for mixing in large tanks where top entry isn’t feasible. Furthermore, magnetic mixers use magnetic coupling for efficient mixing without the need for direct drives.

Static Mixer SK Series Model

|

Model |

Dg(mm) |

dh(mm) |

Q(m3/h) |

|

SK-5/10 |

10 |

5 |

0.15-0.3 |

|

SK-7.5/15 |

15 |

7.5 |

0.3-0.6 |

|

SK-10/20 |

20 |

10 |

0.6-1.2 |

|

SK-12.5/25 |

25 |

12.5 |

0.9-1.8 |

|

SK-16/32 |

32 |

16 |

1.4-3.2 |

|

SK-20/40 |

40 |

20 |

2.2-4.5 |

|

SK-25/50 |

50 |

25 |

3.5-7.0 |

|

SK-32.5/65 |

65 |

32.5 |

5.9-12 |

|

SK-40/80 |

80 |

40 |

9-18 |

|

SK-50/100 |

100 |

100 |

14-28 |

|

SK-62.5/125 |

125 |

125 |

22-44 |

|

SK-75/150 |

150 |

150 |

31-64 |

|

SK-100/200 |

200 |

200 |

56-110 |

|

SK-125/250 |

250 |

250 |

88-177 |

|

SK-150/300 |

300 |

300 |

127-255 |

|

SK-175/350 |

350 |

350 |

173-346 |

|

SK-200/400 |

400 |

400 |

226-452 |

|

SK-250/500 |

500 |

500 |

353-706 |

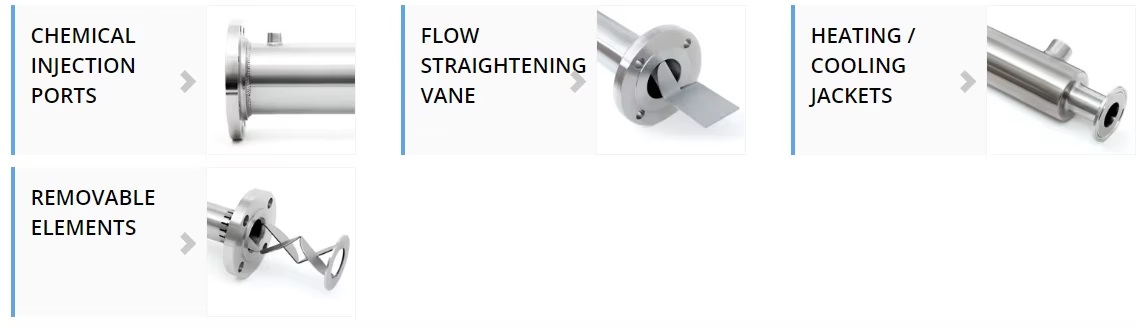

Static Mixer Options

Static Mixer Benefits

Static mixers deliver a high level of mixing efficiency, therefore the consumption of dosed chemicals and formation of byproducts can be dramatically reduced.

They eliminate the need for tanks, agitators, moving parts and direct motive power and they allow to gain highly efficient mixing with low energy consumption.

The energy required for mixing is efficiently extracted as pressure drop from the fluid flow through the elements. Mixers are invariably installed in existing systems without reducing the capacity of existing pumps.

The installation is very easy; no special skills are required other than normal engineering skills.

Mixers have no moving parts and are virtually maintenance free.

Static Mixers are available in all standard pipe sizes and, in the case of open channel designs, are available in any size with no upper limit.

Each Static Mixer is carefully designed to meet the specific requirements of each application.

Static Mixer Applications

Typical applications seen in the water/wastewater industries are mixing of polymer, sodium permanganate, potassium permanganate, sodium hypochlorite, aqueous chemicals, alum, coagulant, chlorine, acid, aluminum sulphate, CO2 gas, NaOH, NaOCI, HCL, antiscalant, flocculant, oily sludge, polyelectrolyte.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China