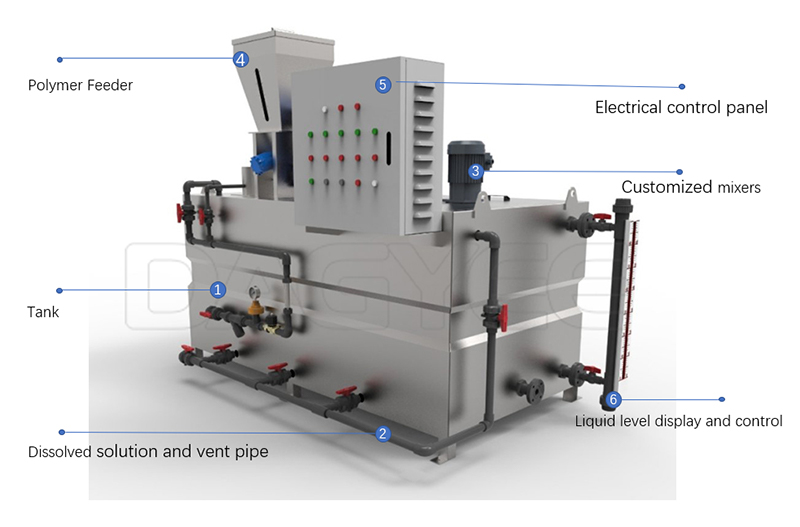

PAM polymer preparation unit Description

Polymer preparation system is a relatively common flocculant preparation device. It is a complete set of equipment with dosing, stirring, liquid conveying, automatic control and integration. It is widely used in raw water in power plants, high-pressure feed water in boilers, and ground collection in oil fields. Dewatering and dewatering treatment systems, various petrochemical systems and wastewater treatment systems. Such as adding coagulant, phosphate, ammonia liquid, lime water, water quality stabilizer (corrosion inhibitor), scale inhibitor, liquid biocide, etc.

Polymer dosing device

Polymer dosing device is composed of hopper, push screw, electric heater and etc. The effective volume of the hopper can meet the dosage for a long time which is equipped with sight glasses for observing material level monitored by the dry powder level meter. The push screw driven by the high-precision reducer can satisfy the dosage. The electric heater can be installed in the discharge pipe of push screw, and it can prevent the powder from caking.

Polymer dissolving device

Polymer dissolving device is composed of pre-soaking device, tank, and 3 sets of mixers. The pre-soaking device is to infiltrate and mix the polymer powder in advance. The 3 tanks are precast mixing tank, homogeneous slaking tank and solution storage tank, in which there is a mixer correspond to guarantee the homogeneity.

Water supply device

Water supply device is composed of pipeline, manual ball valve, filter, pressure gauge, solenoid valve, stop valve, and the rotor flow meter, etc.

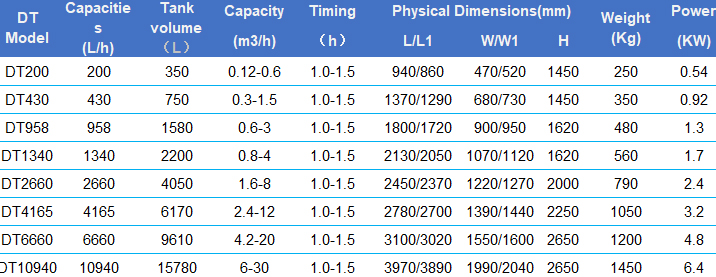

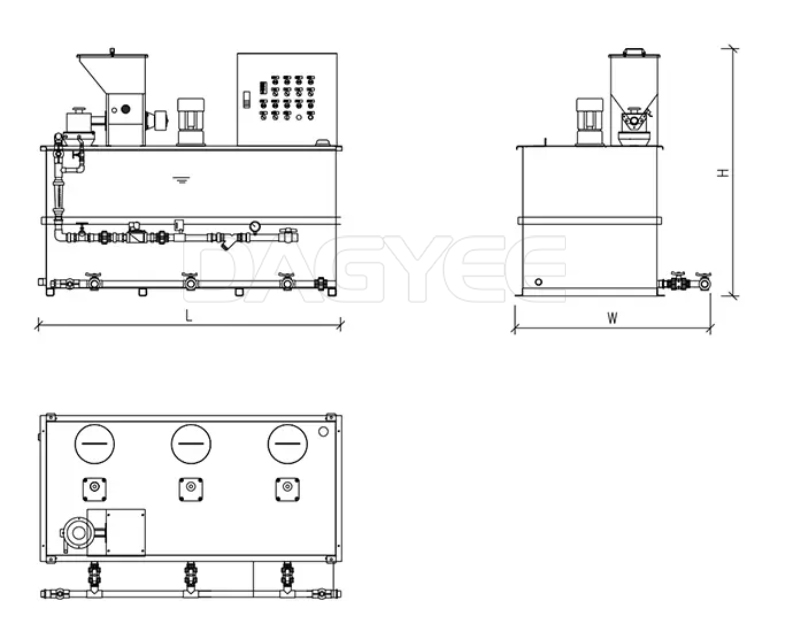

PAM Polymer Preparation Unit Model

PAM Polymer Preparation Function

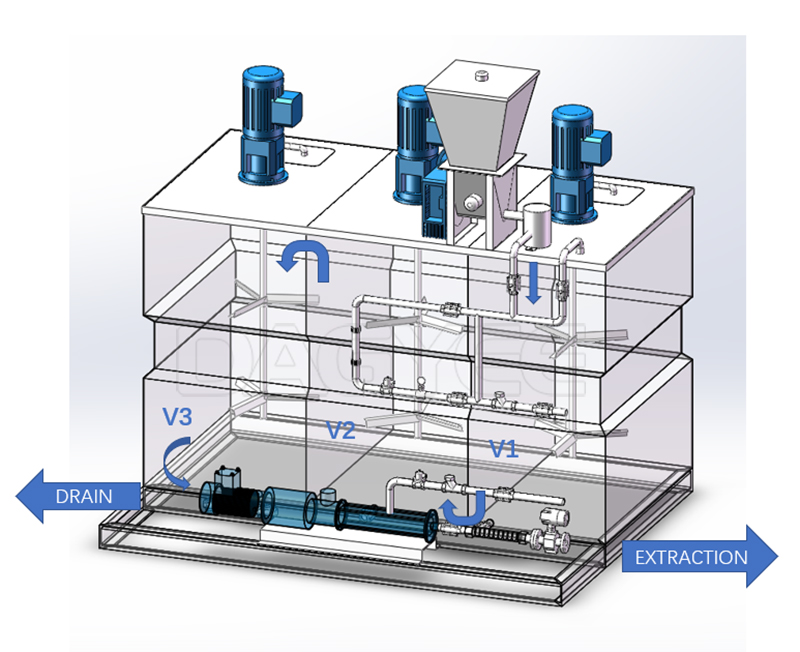

The polymer preparation tank is divided into three chambers: dissolving (V1), maturing (V2) and storage (V3), interconnected by siphons that form a perfect flow between the chambers necessary for the formation of high

quality solution.

The dosed polyelectrolyte comes into contact with water. The water/polyelectrolyte mixture then drops into the tank below where the dissolving phase begins. In this first chamber V1, a slow agitator keeps the contents of the tank moving ensuring thorough homogenization of the solution. The siphon transfers the solution to the maturing chamber, V2, where another slow agitator keeps the solution uniform until maturing is complete. Then the solution is transferred to storage chamber V3 from where it can be transferred for use.

The level switches insta led in this final chamber control the automatic functions:

Max and normal level: when the solution reaches the maximum level, this switch stops the powder dosing unit / liquid polymer dosing pump and closes the water inlet solenoid valve. Whilst level is normal, the switch enables the dosing unit to function and opens the water solenoid valve.

Minimum level: when the solution fa ls to minimum levels and below, this switch stops the dosing pump and sets off an alarm indicator on the electrical control panel.

Overflow level: when the solution reaches the overflow point, this switch stops the powder dosing unit/ liquid polymer dosing pump and closes the water inlet solenoid valve preventing delivery of mixed polymer solution to the drain.

PAM Polymer Preparation Application

Physical chemical treatment, sludge dewatering

Industrial applications: Food & Beverage, Textile, Slaughterhouses, Fish and Meat, Dairy, Recycling industry, Transshipment terminals for ore and coal, Chemical industry, Tank cleaning, Drinking water production, …

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China