DAF systems are widely recognized for their ability to mitigate issues related to sedimentation and gravity thickening methods. Unlike traditional methods, which often rely heavily on the weight of solids to facilitate separation, dissolved-air flotation relies on the buoyancy provided by air bubbles. This shift in mechanism results in enhanced removal efficiencies, especially in low-density or finely suspended particles. Consequently, DAF has emerged as a preferred choice across various industries, particularly where space is limited or where rapid treatment times are necessary.

Dissolved air flotation (DAF) systems remove suspended solids, fats, oils, greases and non-soluble organics by dissolving air into pressurized water. Here’s how this highly efficient dissolved air flotation process works:

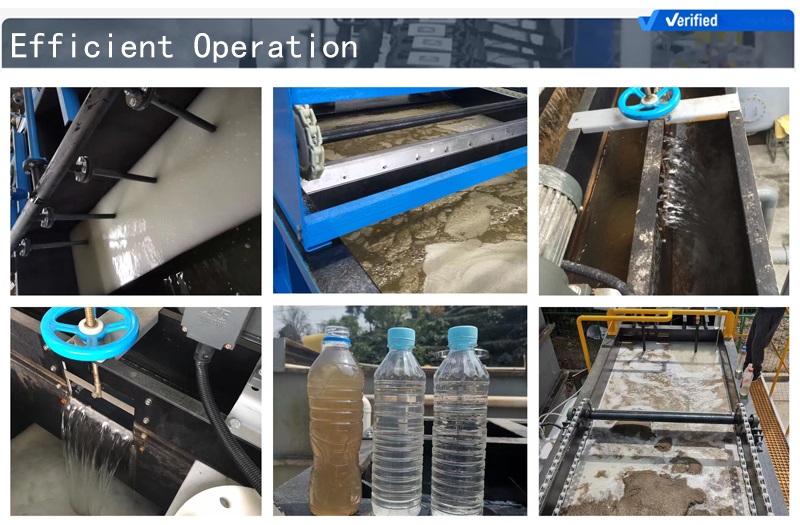

Water enters the WWW™ DAF system through the influent header box to reduce the water’s velocity and distribute it across the length of the vessel. To optimize the treatment process, we design the influent header box with multiple injection points, allowing the introduction of whitewater — a highly saturated pressurized stream of air and DAF effluent that sometimes includes flocculant.

The whitewater forms micro-bubbles and as the wastewater enters the flotation zone, the micro-bubbles attach to the particle surface, lowering the particle density enough to cause suspended solids, fats, oils, greases and non-soluble organics to separate from the wastewater and rise to the surface. The now separated solids, fats, oils, greases and non-soluble organics are skimmed and removed by a chain-and-flight skimmer into the sludge hopper.

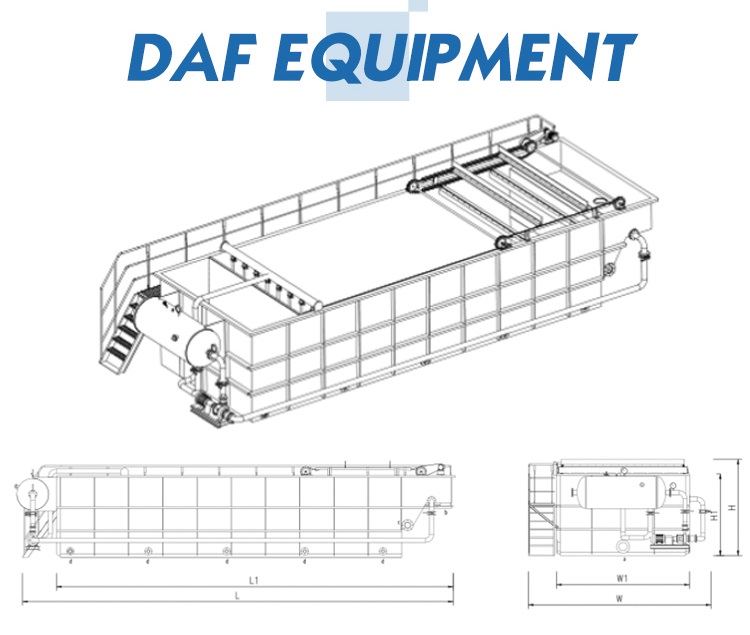

Dissolved air flotation technical sheet

| DAF Model | Qm3/h | Piping Connections | Physical Dimensions(m) | Weight (Kg) | Operating Weight (Kg) |

|---|---|---|---|---|---|

| DAF-003 | 3 |

Inlet: DN50 Outlet: DN50 Sludge: DN100 Vent: DN100 |

L/L1: 3.7/2.8 W/W1: 2.4/1.16 H/H1: 2.2/1.7 |

1500 | 5000 |

| DAF-005 | 5 |

Inlet: DN80 Outlet: DN80 Sludge: DN100 Vent: DN80 |

L/L1: 4/3 W/W1: 2.4/1.16 H/H1: 2.2/1.7 |

1600 | 7000 |

| DAF-010 | 10 |

Inlet: DN100 Outlet: DN100 Sludge: DN100 Vent: DN100 |

L/L1: 4.65/3.8 W/W1: 2.7/1.36 H/H1: 2.4/1.9 |

2000 | 12000 |

| DAF-015 | 15 |

Inlet: DN125 Outlet: DN100 Sludge: DN150 Vent: DN100 |

L/L1: 5.6/4.5 W/W1: 2.9/1.66 H/H1: 2.5/2 |

2200 | 18000 |

| DAF-020 | 20 |

Inlet: DN150 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 5.9/4.8 W/W1: 3.2/1.96 H/H1: 2.5/2 |

3000 | 22000 |

| DAF-030 | 30 |

Inlet: DN150 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 6.8/5.5 W/W1: 3.2/2.16 H/H1: 2.7/2.2 |

3800 | 32000 |

| DAF-040 | 40 |

Inlet: DN200 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 8/6.7 W/W1: 3.6/2.6 H/H1: 2.7/2.2 |

5000 | 45000 |

| DAF-050 | 50 |

Inlet: DN200 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 8.4/7 W/W1: 3.6/2.6 H/H1: 2.7/2.2 |

5500 | 55000 |

| DAF-060 | 60 |

Inlet: DN250 Outlet: DN200 Sludge: DN150 Vent: DN100 |

L/L1: 9.9/8.4 W/W1: 3.8/2.8 H/H1: 2.9/2.4 |

6000 | 66000 |

| DAF-070 | 70 |

Inlet: DN250 Outlet: DN200 Sludge: DN150 Vent: DN100 |

L/L1: 10.4/9 W/W1: 3.8/2.8 H/H1: 2.9/2.4 |

6500 | 75000 |

| DAF-080 | 80 |

Inlet: DN250 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 10.8/9.4 W/W1: 4/3 H/H1: 2.9/2.4 |

7500 | 100000 |

| DAF-100 | 100 |

Inlet: DN300 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 12.1/10.6 W/W1: 4.2/3.2 H/H1: 2.9/2.4 |

9000 | 110000 |

| DAF-120 | 120 |

Inlet: DN300 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 12.5/11.4 W/W1: 4.4/3.4 H/H1: 2.9/2.4 |

10000 | 130000 |

Dissolved air flotation process flow

Improved Water Quality

Greater turbidity reduction

Discharge compliance

Greater treatment flexibility

Reduced chemical consumption

Operational Advantages

Small footprint

Zero backwash

Improved product quality

Simple and easy operation

Reduced downtime and operational cost

The environmental impact of DAF systems is generally positive, particularly in minimizing water pollution. By enabling the removal of over 90% of harmful components from industrial effluents, DAF systems contribute to cleaner water bodies and reduced environmental pollution. Moreover, reduced chemical usage and advancements in energy-efficient designs further enhance the sustainability of DAF technology.

Dissolved air flotation application

Wastewater TreatmentDissolved air flotation systems are commonly used in the following industries and production processes.

Petroleum, petrochemical and refineries

Natural gas processing plants

Pharmaceutical and cosmetics

Mining, quarrying and aggregate production

Water and wastewater treatment

Food processing

Commercial and industrial laundry

Pulp and paper production

Algae removal and desalination pretreatment

Pretreatment for downstream biological treatment systems

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China