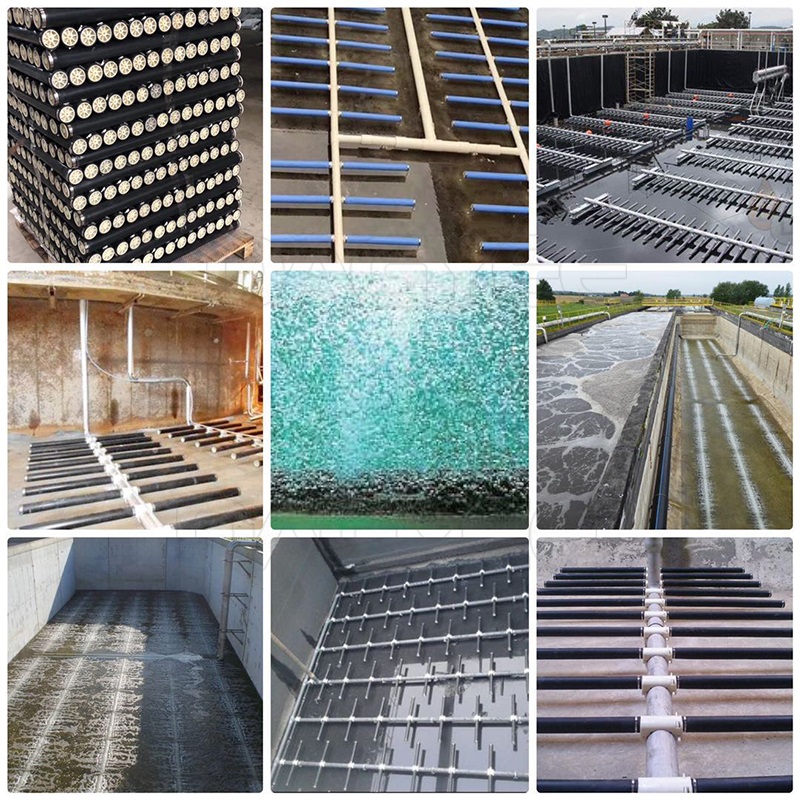

An aeration tube is a core component of modern water and wastewater treatment systems, engineered to efficiently dissolve oxygen into liquids.

Functioning as a fine or coarse bubble diffuser, it introduces a controlled stream of air or oxygen into water bodies, ponds, reactors, or treatment tanks.

This process, known as aeration, is vital for promoting aerobic biological activity, which breaks down organic pollutants, reduces harmful gases like hydrogen sulfide, and maintains healthy dissolved oxygen (DO) levels for aquatic life.

Our advanced aeration tubes are crafted from high-performance materials like reinforced silicone, EPDM, or specialty polymers, offering exceptional resistance to clogging, chemicals, UV radiation, and biological fouling.

Designed for energy efficiency and long-term durability, they are indispensable in diverse settings—from massive municipal sewage plants and industrial effluent facilities to sensitive aquaculture hatcheries and recreational pond management.

By ensuring optimal oxygen transfer efficiency (OTE), these tubes significantly enhance treatment capacity, reduce operational costs, and support sustainable environmental management practices.

Aeration tube WWTP function

1. Oxygen Transfer & Dissolution

The primary function is to dissolve gaseous oxygen into water by creating a vast surface area of air bubbles.

Fine bubble tubes generate tiny bubbles that rise slowly, maximizing contact time and oxygen absorption to elevate dissolved oxygen concentrations efficiently.

2. Biomass Support & Mixing

Beyond oxygenation, the upward flow of bubbles creates gentle vertical mixing in the water column.

This prevents stratification, ensures uniform distribution of heat, nutrients, and microorganisms, and keeps biological flocs in suspension, optimizing the treatment process.

3. Odor & Volatile Compound Stripping

The aeration process facilitates the physical stripping of undesirable gases, such as hydrogen sulfide (causing rotten egg smell), methane, and other volatile organic compounds (VOCs), from the water into the atmosphere, thereby controlling odors and improving safety.

4. Biochemical Oxidation Promotion

By supplying essential oxygen, the tube enables and accelerates aerobic biochemical oxidation.

This is crucial for microorganisms to metabolize and decompose organic matter (BOD/COD), ammonia (via nitrification), and other contaminants, converting them into harmless substances.

Aeration tube WWTP model

| Model | φ63*500 | φ63*750 | φ63*1000 |

| MOC |

EPDM/Silicon membrane ABS/PP carrier plate |

EPDM/Silicon membrane ABS/PP carrier plate |

EPDM/Silicon membrane ABS/PP carrier plate |

| Length | 500mm | 750mm | 1000mm |

| Connector | 3/4 NPT | 3/4 NPT | 3/4 NPT |

| Flow range | 2-14 m³/h | 5-20 m³/h | 6-28 m³/h |

| Bubble Size | 0.8-2mm | 0.8-2mm | 0.8-2mm |

| Service Area | 0.75-2.5 m² | 1.0-3.0 m² | 1.5-3.5 m² |

| Service Life | >8 year | >8 year | >8 year |

Aeration tube WWTP advantage

High Oxygen Transfer Efficiency (OTE)

Engineered to produce a high density of fine bubbles, our tubes achieve superior OTE compared to coarse bubble alternatives.

This means more oxygen is dissolved per unit of energy consumed, leading to direct and significant energy cost savings.

Exceptional Clogging Resistance

Featuring self-cleaning membrane surfaces or specialized pore structures, these tubes resist clogging from biological growth, mineral scaling, and suspended solids.

This maintains consistent performance and dramatically reduces maintenance frequency and costs.

Long Service Life & Durability

Constructed from premium, UV-stabilized, and chemically inert materials, the tubes withstand harsh environments, including abrasive sludge, oxidizing agents, and fluctuating pH levels.

This robustness ensures a long operational lifespan and a high return on investment.

Energy & Operational Cost Savings

The combination of high OTE and low clogging translates directly into lower blower energy requirements and reduced downtime for cleaning.

This results in substantially lower total lifecycle operating costs for the treatment facility.

Uniform Aeration & Process Stability

Designed for even air distribution along the entire length, they prevent dead zones and ensure consistent oxygen availability throughout the tank or pond.

This stability leads to predictable, high-quality treatment outcomes and robust process control.

Easy Installation & Flexibility

Available in various lengths and diameters with flexible or modular designs, these tubes are easy to install, retrofit into existing grids, or reconfigure.

They are compatible with a wide range of drop pipes, headers, and air supply systems.

Aeration tube WWTP feature

Made from high-grade silicone or EPDM rubber, offering excellent elasticity, tear resistance, and impermeability to water, ensuring consistent bubble size and preventing water backflow.

Reinforced Structural Design

Incorporates internal fabric or polymer supports to prevent collapse, kinking, or deformation under hydrostatic pressure and continuous operation, guaranteeing long-term structural integrity.

Precision Perforation or Pore Structure

Utilizes laser-cut perforations or engineered micro-pores to generate consistent, fine bubbles (typically 1-3 mm) for maximum surface area and oxygen dissolution efficiency.

Integrated Weighting System or Anchoring Options

Some models include built-in weighted strips or offer easy-clip anchors for secure placement on tank floors without floating, ensuring optimal positioning for effective aeration.

Chemical & Abrasion-Resistant Formulation

The material compound is specifically formulated to resist degradation from ozone, chlorine, acids, alkalis, and abrasive particles commonly found in industrial wastewater.

Modular Connection System

Features standardized end fittings (e.g., barbed, threaded, or quick-connect) for secure, leak-proof connections to air distribution pipes, allowing for easy assembly and scalability.

Aeration tube WWTP application

Used in activated sludge processes, aeration basins, and sequencing batch reactors (SBRs) to provide the oxygen necessary for microorganisms to break down organic sewage and nutrients, ensuring effluent meets discharge regulations.

Industrial Effluent Treatment (Chemical, Pharmaceutical, Food & Beverage)

Critical for treating high-strength organic and chemical wastewater from manufacturing.

Aeration tubes facilitate the biological degradation of complex pollutants, helping industries comply with stringent environmental standards.

Aquaculture & Fish Farming

Essential for maintaining life-supporting dissolved oxygen levels in fish ponds, shrimp tanks, and hatchery raceways.

Prevents fish kills, supports higher stocking densities, and promotes healthy growth rates.

Pond & Lake Management/Restoration

Applied in recreational lakes, decorative ponds, and eutrophic water bodies to combat algae blooms, improve water clarity, eliminate odors, and restore ecological balance by supporting aerobic conditions.

MBBR/IFAS Fixed-Film Bioreactors

Serves as the aeration heart in Moving Bed Biofilm Reactor (MBBR) or Integrated Fixed-Film Activated Sludge (IFAS) systems, providing oxygen to biofilm-coated carrier media for highly efficient, compact biological treatment.

Sludge Digestion & Composting

Used in aerobic digesters and sludge composting operations to supply oxygen to aerobic bacteria, accelerating sludge stabilization, reducing volume, and minimizing pathogens and odors.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China