Our Industrial UPVC Static Mixer is a high-efficiency, maintenance-free inline mixing solution engineered specifically for aggressive water treatment environments.

Constructed from high-grade Unplasticized Polyvinyl Chloride (UPVC), this mixer offers exceptional resistance to corrosion, chemicals, and scale buildup.

Unlike dynamic mixers, our unit utilizes a series of fixed helical mixing elements housed within a pipe to blend fluids, gases, or solids continuously with zero moving parts.

Ideal for dosing applications such as pH adjustment, flocculation, and chlorination, this UPVC static mixer ensures homogeneous output with minimal pressure drop, making it the most cost-effective choice for marine, municipal, and industrial water systems.

UPVC static mixer function

Function 1: Helical Mixing Element Geometry

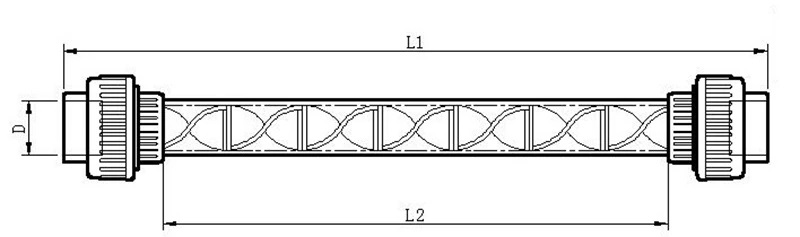

The internal core of the mixer consists of rigid, right/left-hand helical elements precisely fixed at 180° angles.

This alternating geometry creates flow division and radial mixing.

As the media passes through, it is split, rotated, and recombined exponentially with each element, ensuring complete homogeneity of additives regardless of flow rate variability.

Function 2: Flanged End Connections

Designed for rapid inline installation, this mixer features industry-standard socket flanges molded directly onto the UPVC body.

These flanges ensure leak-proof connections when bolted to existing pipelines and allow for easy removal for system inspection or cleaning, without disturbing the pipeline alignment.

Function 3: No Internal Moving Parts

The mixer operates entirely on hydraulic pressure.

With zero shafts, bearings, or seals, there are no mechanical parts to lubricate, replace, or fail.

This design eliminates the risk of contaminating the water stream with grease or metal fragments and guarantees silent operation.

UPVC static mixer model

| Model NO. | D(mm) | L1(mm) | L2(mm) | Flow(m³/h) |

| DN15 | 20 | 252 | 156 | 0.4~1 |

| DN20 | 25 | 330 | 225 | 0.6~1.8 |

| DN25 | 32 | 420 | 292 | 1~3.2 |

| DN32 | 40 | 495 | 336 | 1.4~6 |

| DN40 | 50 | 565 | 406 | 2.2~10 |

| DN50 | 63 | 695 | 497 | 3.5~20 |

| DN65 | 75 | 900 | 642 | 10~60 |

| DN80 | 90 | 880 | 770 | 15~80 |

| DN100 | 110 | 990 | 850 | 30~120 |

UPVC static mixer advantage

Total Chemical Resistance: Impervious to corrosion from acids, alkalis, salts, and chlorine, unlike stainless steel mixers which are prone to pitting.

Zero Maintenance: "Fit and Forget" design. No moving parts means no spare parts inventory or downtime for repairs.

Lightweight Construction: UPVC is significantly lighter than metal, reducing shipping costs and requiring less structural support during installation.

Scale & Bacteria Resistant: The smooth bore surface prevents the adhesion of lime scale, biofilm, and algae, ensuring consistent flow over time.

Transparent Wall Option: Available in clear PVC variants, allowing visual inspection of the mixing process and early detection of air pockets or debris.

Energy Efficient: Low pressure drop per element reduces the workload on feed pumps, lowering electricity consumption compared to mechanical agitators.

Cost-Effective Material: Lower raw material cost than 316L or Duplex stainless steel, offering superior performance at a fraction of the price.

UV Resistant Formulation: Manufactured with UV-stabilized compounds to prevent brittleness and discoloration when installed in direct sunlight.

UPVC static mixer features

Material: High-impact rigid UPVC (Lead-Free compliant for potable water).

Element Geometry: 180° alternating helices, fully fixed (non-removable).

Size Range: Available in DN15 (1/2") through DN400 (16") diameters.

Pressure Rating: Rated for 150 PSI at ambient temperatures (23°C).

Connection Type: Integrally molded ANSI/DIN socket flanges (Plain ends available upon request).

Temperature Range: Maximum operating temperature of 60°C (140°F).

UPVC static mixer applications

pH Control Systems: Intimately mixing acid or caustic soda into effluent streams to achieve neutralization prior to discharge.

Polymer/Flocculant Dosing: Diluting and activating viscous polymers for sludge dewatering and clarifier feed.

Chlorination & Dechlorination: Ensuring uniform dispersion of sodium hypochlorite or sulfur dioxide for disinfection and dechlorination.

Seawater Reverse Osmosis (SWRO): Mixing antiscalants and coagulants into seawater feed to prevent membrane fouling.

Cooling Towers: Blending biocides and corrosion inhibitors into recirculating water to control Legionella and scaling.

Heavy Metal Precipitation: Combining lime slurry or sulfide solutions with wastewater to precipitate dissolved metals.

Food & Beverage CIP: Mixing cleaning detergents and sanitizers with water in Clean-in-Place circuits (where low temp applies).

Aquaculture: Oxygenation and mixing of treatment chemicals in recirculating aquaculture systems (RAS).

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China