Belt filter press description

Belt filter presses are used to remove water from liquid wastewater residuals and produce a non-liquid material referred to as “cake.” Dewatering wastewater solids reduces the volume of residuals, improves operation, and reduces costs for subsequent storage, processing, transfer, end use, or disposal among other benefits.

Belt filter press principle

A belt filter press (BFP) provides sludge dewatering by pressing the sludge to force the water through a permeable medium. The process produces a cake (the dewatered product) having a dry solids (DS) content of 30% or more in the case of primary sludge. This is to be distinguished from the lower-energy gravity belt thickener process which achieves a maximum DS content of ~10%.

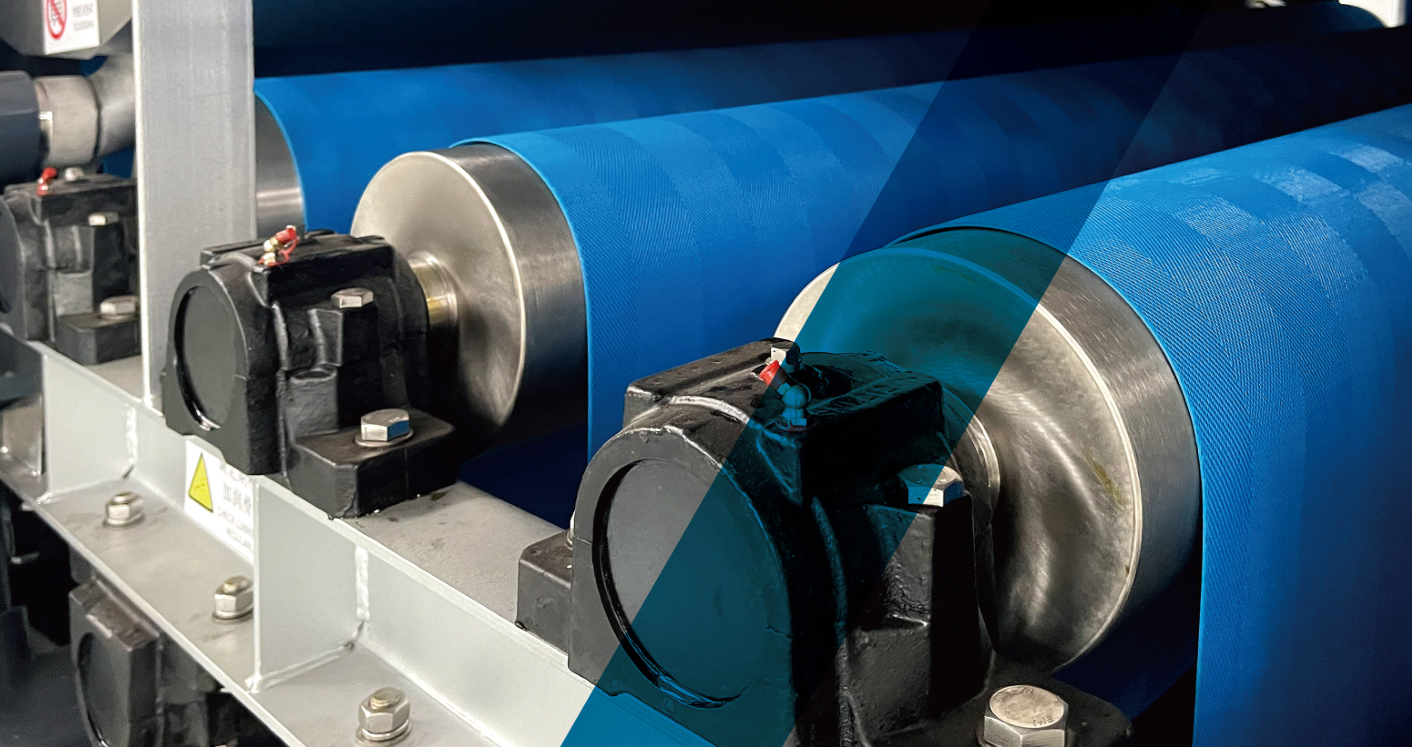

A BFP combines drainage and mechanical pressure sequentially to remove water. The equipment normally comprises 2−3 recirculating belts, with two belts combining at some point to compress the sludge and squeeze water from it.

The conditioned sludge feed is first conveyed along a gravity drainage section of one of the porous belts, as with a gravity belt thickener. It is then subject to pressure as it is passed between two recirculating belts, forming a wedge zone at the inlet, which travel over a roller. This squeezing action from the two belts in this pressure zone releases more water.

Many belt filter press technologies contain a second pressure zone comprising a series of rollers through which the two belts pass with the sludge solids retained between them. The rollers in this high pressure zone apply tensioning (i.e. stretching) to the belts, exerting both shearing and compressive forces on the sludge which further release more water.

Some BFP technologies are based on a three-belt system, where the gravity belt is independent of the two pressurising belts. This allows the recirculation rate for the thickening operation to be separately adjusted from the dewatering operation.

In common with the gravity belt thickener, the belts are subject to cleaning with water spray to limit the plugging of the filter belt pores. The waste washwater is combined with the filtrate.

The overall performance of the BFP is dependent on the feed sludge source and characteristics and the dosing conditions. As with all other thickening and dewatering technologies, primary sludges – both raw and anaerobically digested – are more readily filtered than waste activated sludge (WAS).

Belt Filter Press Advantage

Belt filter press features

Belt filter press for municipal and industrial sludge

High-performance belt filter press for best dewatering results

Combi-unit: thickening and dewatering in one working process

Feed capacity up to 1000 kgDR/h

Three sizes available

Versatile sludge press

High efficiency (low polymer and power consumption)

High capacity (due to extended predewatering zone)

Application-optimized design

Belt filter press applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China