Belt filter press description

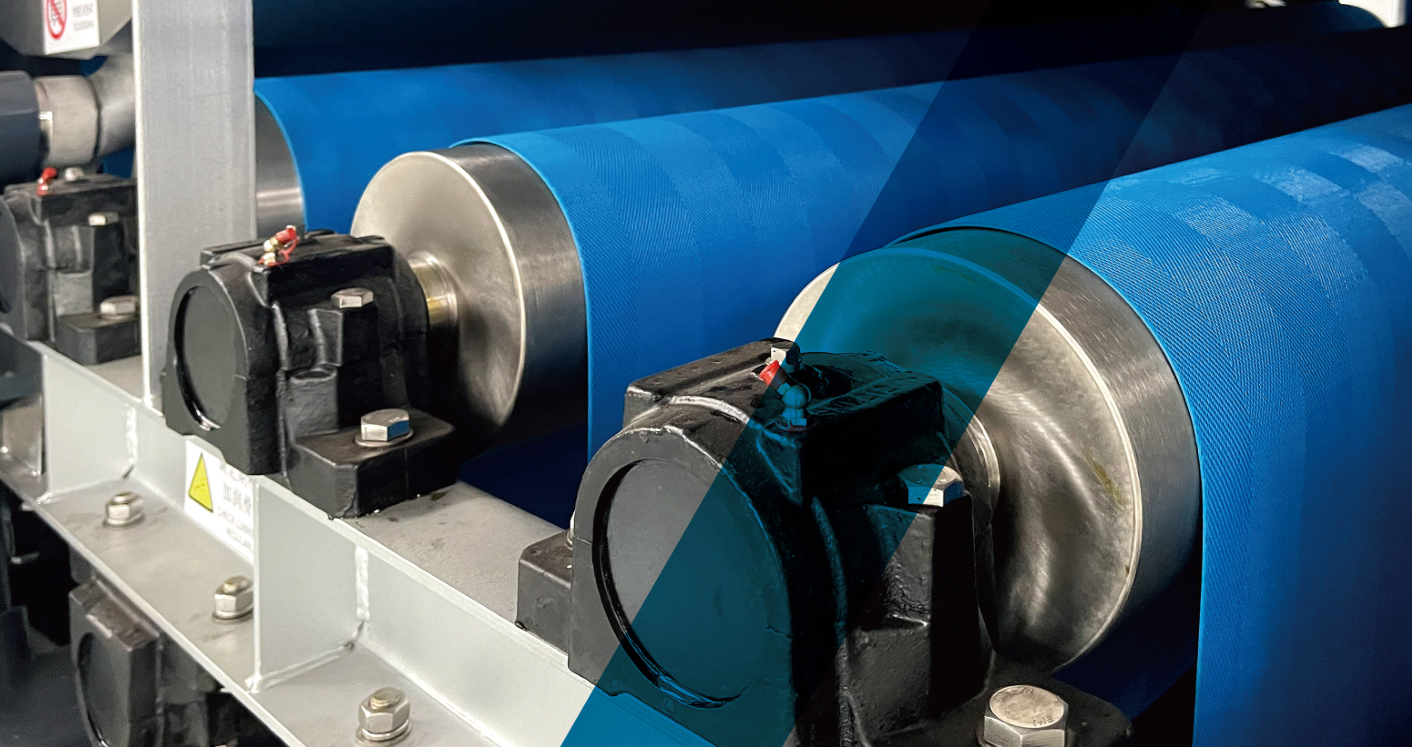

A Belt Filter Press is a sludge dewatering device that applies mechanical pressure to a chemically conditioned slurry, which is sandwiched between two tensioned belts, by passing those belts through a serpentine of decreasing diameter rolls. The machine can actually be divided into three zones: the gravity zone, where free draining water is drained by gravity through a porous belt; the wedge zone, where the solids are prepared for pressure application; and the pressure zone, where medium, then high pressure is applied to the conditioned solids.

Belt filter press principle

A belt filter press (BFP) provides sludge dewatering by pressing the sludge to force the water through a permeable medium.

Belt Filter Press Advantage

Belt filter presses offer numerous advantages, including high efficiency, reduced operational costs, and minimal maintenance needs.

They can process a large volume of material continuously, making them ideal for large-scale operations.

Additionally, they produce dry cake with a low residual moisture content, enhancing disposal and further processing.

Belt filter press features

Belt filter press applications

Belt filter presses can be used to dewater most biosolids generated at municipal wastewater treatment plants and are a common type of mechanical dewatering equipment.

Using mechanical equipment to dewater solids may not be the most cost effective alternative for wastewater treatment plants operating at less than about 4 mgd.

The selection of dewatering equipment should be based on the results of a site specific biosolids management plan which identifies both processing and end use alternatives and estimates costs.

It may be less expensive to haul liquid to an application site or pay a processing facility to dewater and process or landfill the dewatered cake.

Smaller facilities should also evaluate non-mechanical dewatering methods, such as drying beds or reed beds.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China