Belt filter press description

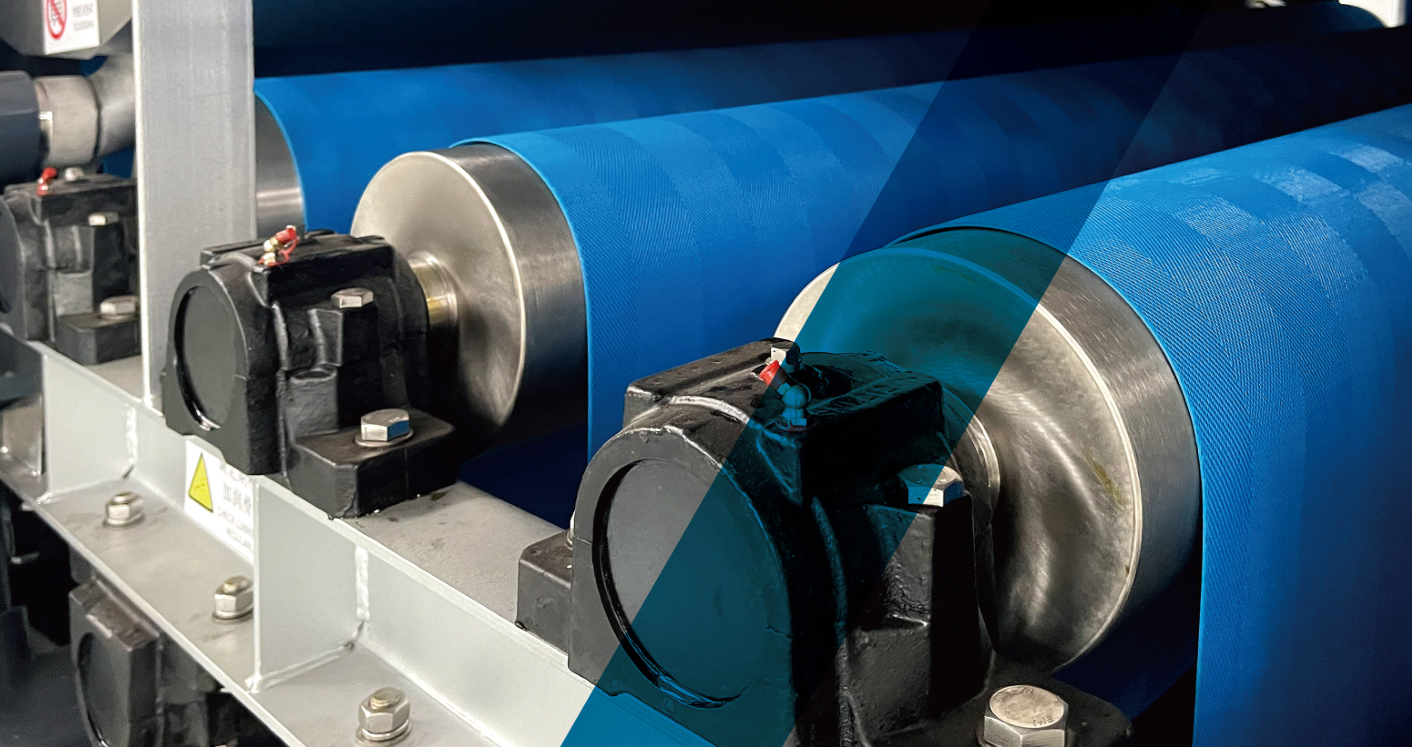

The belt filter (sometimes called a belt press filter, or belt filter press) is an industrial machine, used for solid/liquid separation processes, particularly the dewatering of sludges in the chemical industry, mining and water treatment. Belt filter presses are also used in the production of apple juice, cider and winemaking. The process of filtration is primarily obtained by passing a pair of filtering cloths and belts through a system of rollers. The system takes a sludge or slurry as a feed, and separates it into a filtrate and a solid cake.

Belt filter press principle

Belt filter presses are used to dewater primary and/or waste activated sludges (WAS), such as those that come from aerobic or anaerobic digestion.

Belt filter presses are manufactured as either two-belt or three-belt units. The current preference is that belt filter presses have three belts, which enables the gravity zone to operate independently from the pressing zones. Belt filter presses basically have three different zones:

■ gravity zone,

■ medium pressure zone (wedge zone), and

■ high pressure zone (shear zone).

Solids must be conditioned with polymer prior to being applied to a belt filter press. The polymer is used to release the water from the solids so that most of the water is removed on the gravity zone and additional water is then removed in the pressing zones.

Approximately 60% to 70% of the water should be removed through the gravity zone with the remaining water removed in the wedge and shear zones.

Belt Filter Press Advantage

Belt filter press features

Belt filter press applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China