Belt filter press description

DAGYEE belt presses are ideal for efficient dewatering of sludge from municipal and industrial wastewater treatment as well as fresh water production at waterworks.

Belt filter press principle

Material Input: The material is generally a slurry that includes solid particles and liquid residing within the mixture. This material is fed to the belt press.

Transport: The system transports material evenly in a porous belt. In addition, this belt, typically made from a strong fabric or synthetic material, allows fluids to drain while retaining solids.

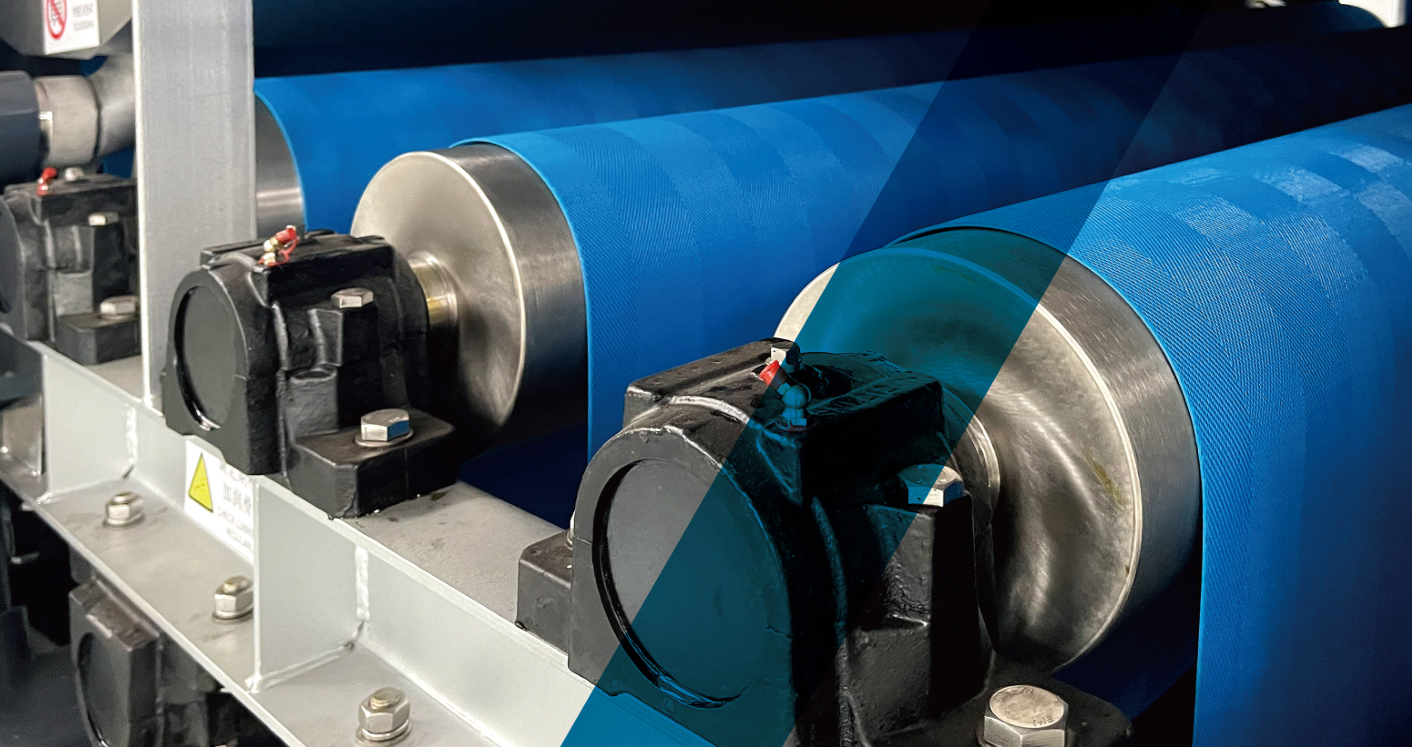

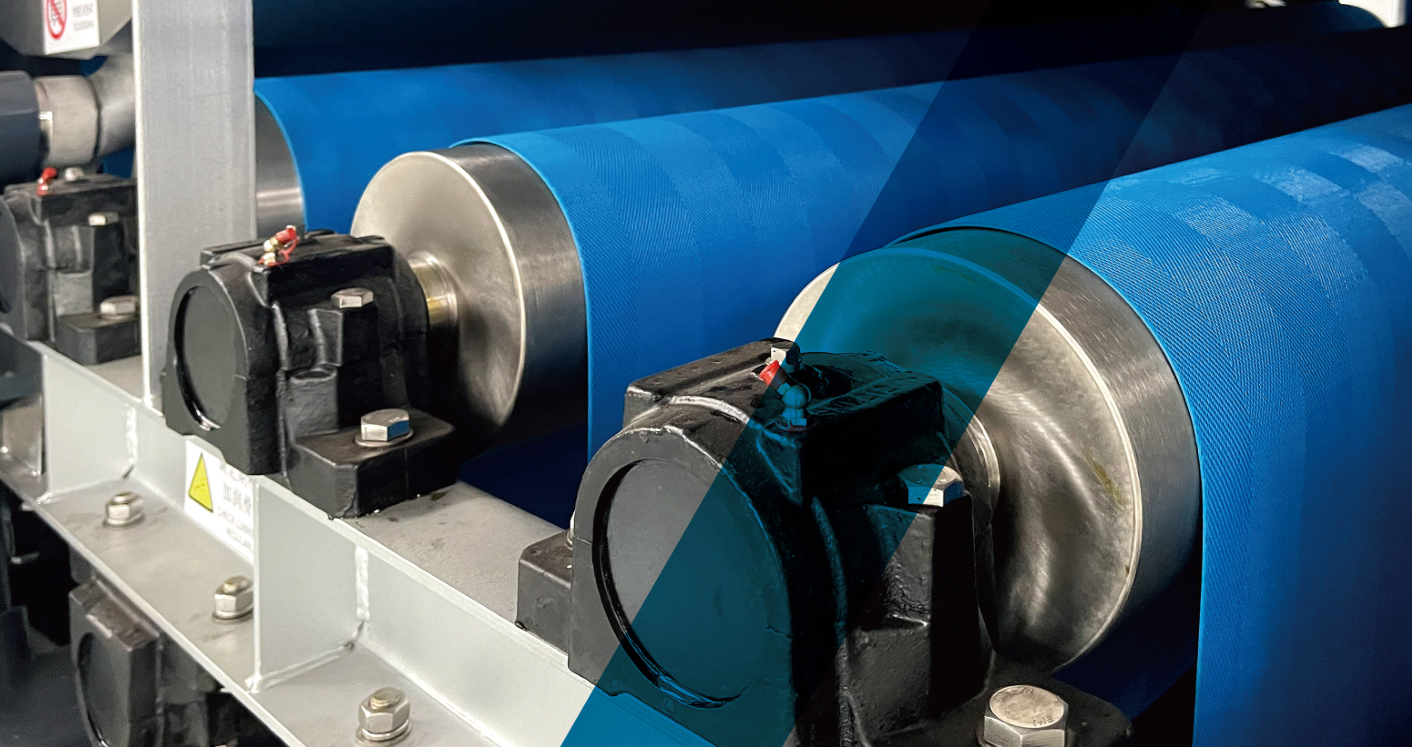

Roll Pressure: The system rolls the material (known as roll pressure) through a series of rollers, each with increasing amounts. Additionally, between these rollers, the belt moves, pressing the material against one aspect and thereby forcing any liquid out.

Dewatering: As the material travels throughout the press, the system expresses water into a tray. Meanwhile, the system allows the rest of the solid, which is now considerably drier, to keep creeping down.

Filter cake (solids): The system dehydrates the sludge and discharges it at the end of the press. And then it’s either for further processing or for disposal.

Belt Filter Press Advantage

-

Low-profile structure for a smaller machine footprint and ease of access for operator (no platform needed)

-

Continuously increasing pressure for perfect dewatering

-

Highest throughput of up to 50% more than comparable competitor machines

-

Lowest residual moisture of final product thank to extended dewatering area (7, 8 or 12 S-rolls)

-

Flexibility increased by modular design

-

Low energy requirement, reduction of polymer consumption, ease of maintenance, and hydraulic capacity increased for significant cost savings and best operator safety

Belt filter press features

-

A choice of 2 or 3 belt dewatering systems with standard, extended, or independent gravity zones for consistently high cake solids in varying sludge conditions

-

When higher hydraulic sludge capacities need to be treated, the drainage zone is extended by installing a thickening stage before the actual dewatering process

-

Increase of the effective filtration areas

-

Innovative low pressure zone concept consisting of a big diameter perforated roll substitution in the traditional wedge area

-

Effective high pressure zone (increase of pressure intensity and time)

-

The possibility to install 5-7-9-11 rolls in final high pressure zone allows the machine to be configured per the application characteristics and required performance

Belt filter press applications

Wastewater Treatment: Belt presses process sludge by extracting moisture, which in turn reduces the volume. Consequently, this helps lessen waste transport and disposal costs.

Food and Beverage Industry: The process uses belt presses to produce juice from fruits such as apples and grapes. These presses allow for easy extraction of the press cake from the pulp.

Mining industry: In order to minimize the amount of waste material, it needs dewatering of mineral slurries. This process includes separation, recovery, and discharge of valuable minerals.

Agriculture: Farmers need to manage animal manures or other agricultural byproducts. Consequently, they do this to reduce their water content and decrease the volume of waste.