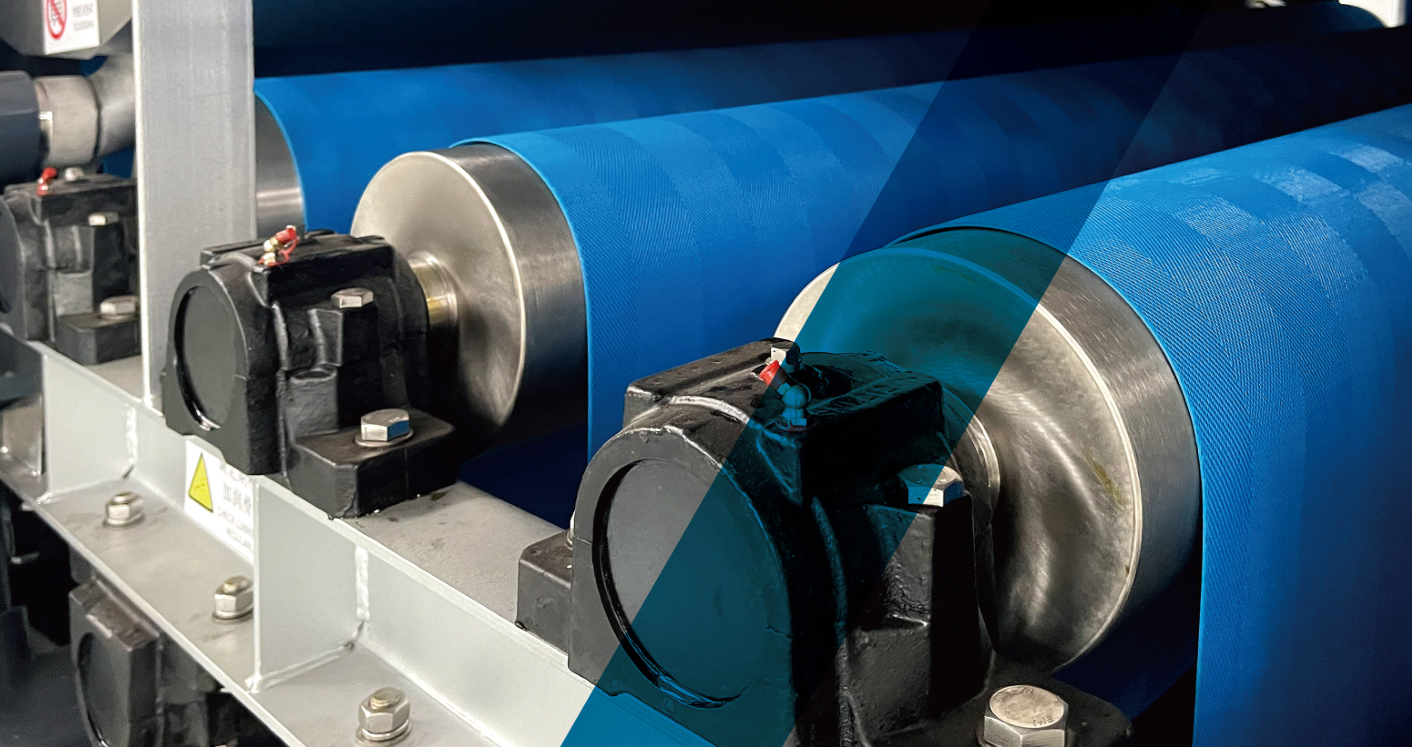

Belt filter press description

Belt filter presses can be used to dewater most biosolids generated at municipal wastewater treatment plants and are a common type of mechanical dewatering equipment.

Belt Filter Press Advantage

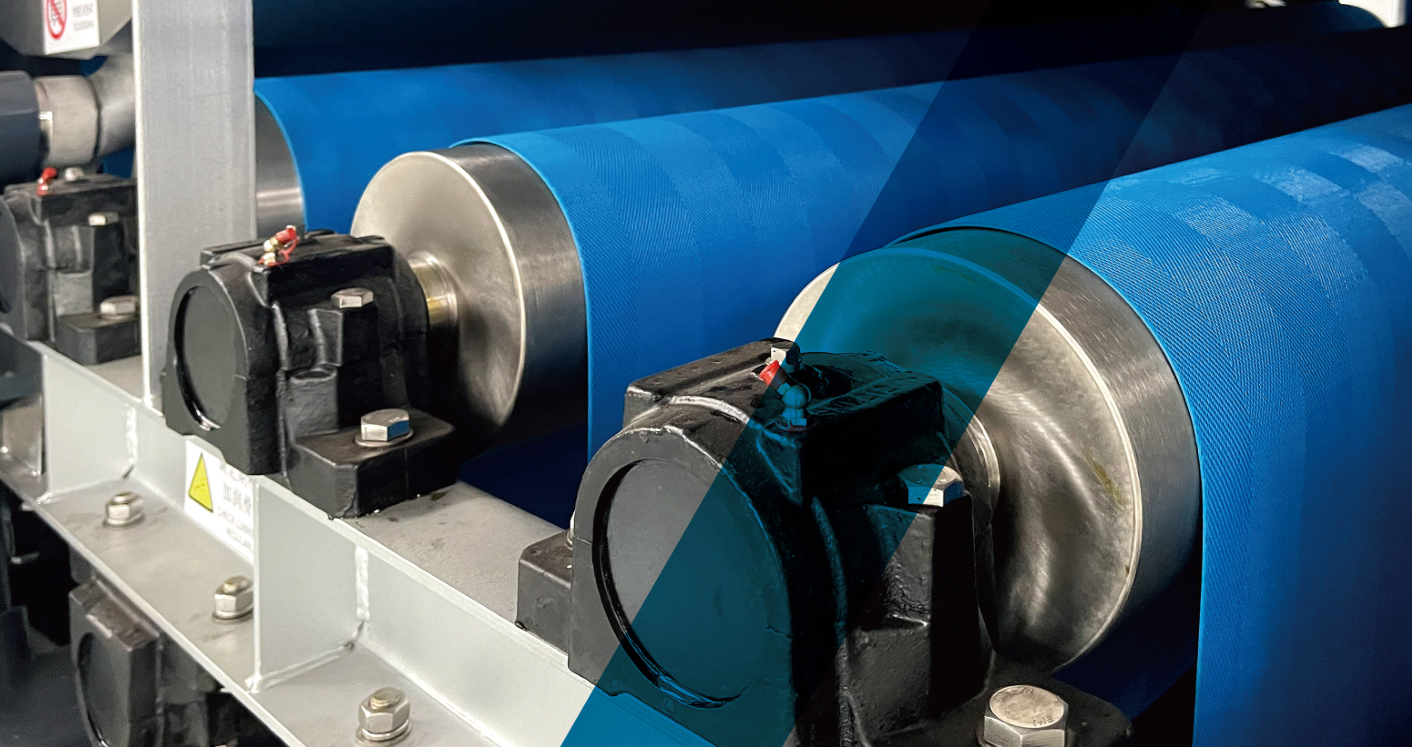

Belt filters are considered simple and reliable, with good availability, low staffing, easy maintenance and a long life. The belt filter is most advantageous when installed such that it is open and viewable at floor level for easier adjustment and monitoring. This is of course subject to what lighting and ventilation will allow.

The belt filter press is often used in wastewater treatment, and thus the odour of the feed sludge, volatile emissions and the chemicals used in treatment, may become a problem. One control method is to use odour-neutralizing chemicals such as potassium permanganate. However this only neutralizes odours and doesn’t affect any gases or chemicals involved. Although all problems can be controlled by enclosing the filter, the enclosure reduces essential visibility and easy access to the machine for maintenance and repairs, leading to the expensive automation of the process.

A belt filter press is also known for its high capacity throughput, as it is designed to handle excess capacity. It has low initial costs and low energy running costs, however, if throughput is less than 4 million gallons per day, the belt filter press may be less cost efficient than liquid transport, hiring a processing facility, or utilizing non-mechanical dewatering methods such as drying beds or reed beds.

Belt filters are less effective at processing some feeds. Unless the feed is well mixed from a digester, the use of belt filters will be more costly when processing a feed with varying solids content as this requires more operator attention, raising staffing costs. Feeds with high grease and oil content can lower the solids percentage in the cake by blinding the belt filter and all feeds need to be screened to protect the belt from being damaged by sharp objects. The type of feed may also affect the washing process. The belt filter needs to be washed frequently which consumes large amount of water and time. Water and time wastage, as well as the associated costs can be reduced by automating the washing system and using effluents.

Belt filter press features

Belt press filters are designed for solids capacity, by weight or volume, rather than wastewater flow. Solids concentration must be determined based on the concentration of primary solids in the feed and further solids that may precipitate during treatment. Solids concentration for a process will vary, thus the design must have the capacity to deal with varying feed solids concentration.

The feed to a belt press filter depends on the type of solids, desired product and filter design. For most sludge types the feed dry solids concentration is typically in the range of 1-10%. The resulting dewatered sludge (or cake) dry solids concentration typically falls in the range of 12-50%. Dilute feed solids concentration results in a cake of higher moisture content whilst a higher feed solids concentration yields an improved solids filtration rate and drier end product.

Belt filter press applications

The belt filter is mainly used for dewatering of sludge and slurry and juice extraction from apples, pears and other fruits, as well as grapes for winemaking, etc. Belt filters are used both municipally and industrially in a range of areas including urban sewage and wastewater treatment, metallurgy and mining, steel plants, coal plants, breweries, dyeing, tanneries, as well as chemical and paper factories.