Belt filter press description

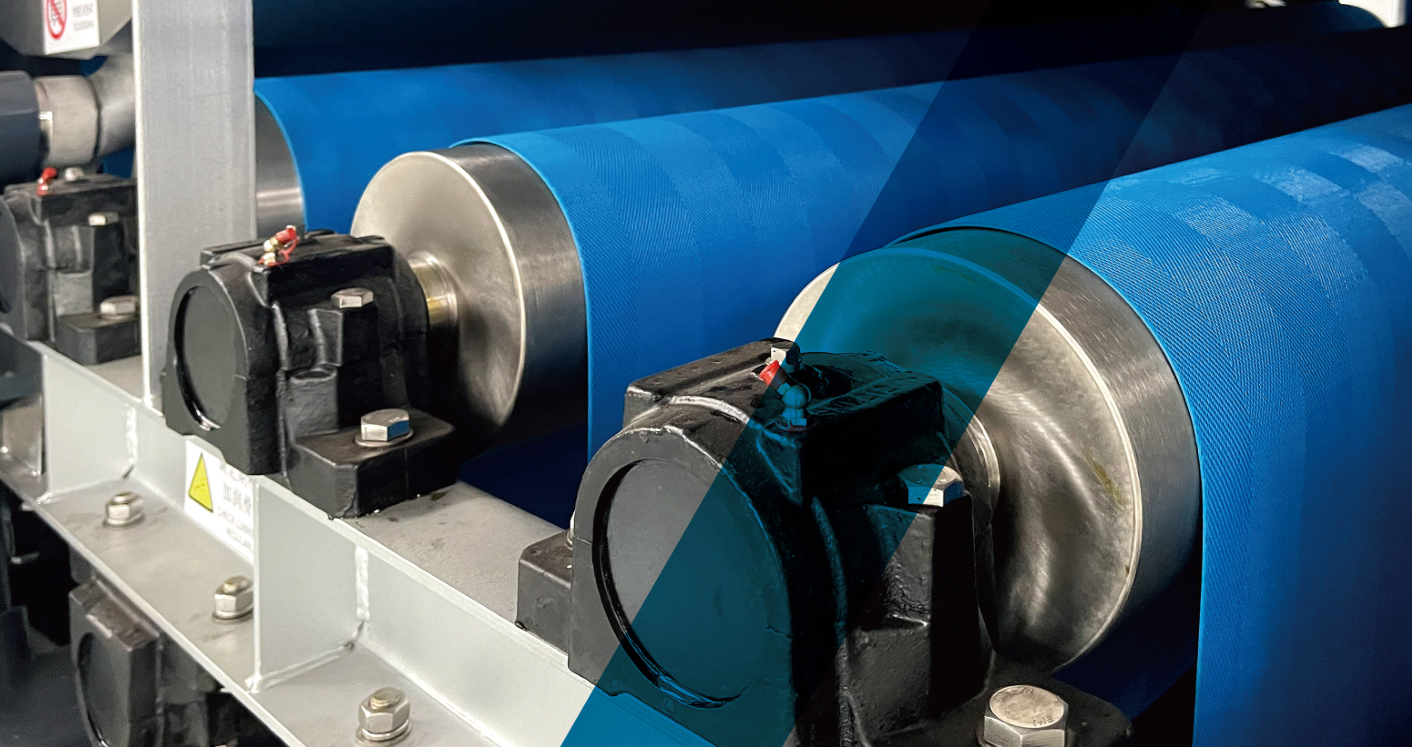

A Belt Filter Press is a sludge dewatering device that applies mechanical pressure to a chemically conditioned slurry, which is sandwiched between two tensioned belts, by passing those belts through a serpentine of decreasing diameter rolls. The machine can actually be divided into three zones: the gravity zone, where free draining water is drained by gravity through a porous belt; the wedge zone, where the solids are prepared for pressure application; and the pressure zone, where medium, then high pressure is applied to the conditioned solids.

Belt filter press principle

Belt presses are a common type of mechanical dewatering equipment used to dewater most biosolids generated at municipal wastewater treatment plants and many industrial applications. Belt presses are used to remove water from liquid wastewater residuals and produce a non-liquid material referred to as “cake”. The Belt Filter Press is a broadly applicable product for dewatering municipal biosolids and industrial sludges. Since this is a continual process, it is effective on high-volume waste streams where a large production of low-quality filter cake is acceptable.

Many belt press designs and filtration processes are available, but all incorporate the following basic features: polymer conditioning zone, gravity drainage zones, low pressure squeezing zone, and high pressure squeezing zones. A belt filter dewaters biosolids or industrial sludges by applying pressure to squeeze out the water or liquid phase. Belt Filter Presses are available in a three-belt, a two-belt, and an extended gravity two-belt design. Advanced designs provide a large filtration area, additional rollers, and variable belt speeds that can increase cake solids.

Belt Filter Press Advantage

Belt filter press features

Belt filter press applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China